ZR-YJV22-26/35kV high voltage power cables represent one of the most reliable solutions for modern power transmission and distribution systems. With their exceptional electrical properties, flame-retardant characteristics, and robust mechanical construction, these cables have become the preferred choice for critical infrastructure projects worldwide. This comprehensive guide explores the technical specifications, performance advantages, and practical applications of ZR-YJV22-26/35kV cables to help engineers and procurement specialists make informed decisions.

Technical Specifications

Basic Parameters:

- Rated Voltage: 26/35kV

- Conductor Material: Annealed copper

- Insulation: Cross-linked polyethylene (XLPE)

- Sheath: Polyvinyl chloride (PVC)

- Armor: Double steel tape armor

- Flame Retardant: Yes (ZR designation)

- Maximum Conductor Temperature: 90°C (normal operation), 250°C (short circuit, max 5 seconds)

- Minimum Installation Temperature: 0°C

Available Conductor Configurations:

- 3-core designs with various cross-sections (e.g., 3×50mm², 3×120mm², 3×185mm², 3×240mm², 3×300mm²)

- Custom configurations available upon request

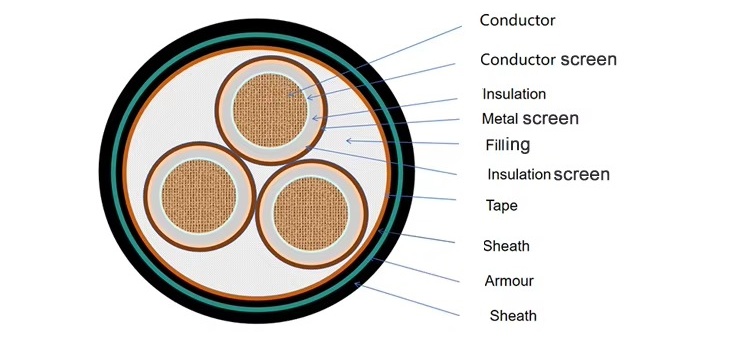

Cable Construction and Materials

The ZR-YJV22-26/35kV cable features a sophisticated multi-layer design that ensures optimal performance under demanding conditions:

- Conductor: High-purity copper conductors with compact stranded construction to minimize electrical resistance and maximize current carrying capacity.

- Conductor Shield: Semi-conductive layer that ensures uniform electric field distribution and prevents partial discharges.

- Insulation: Cross-linked polyethylene (XLPE) providing excellent dielectric properties and thermal stability.

- Insulation Shield: Semi-conductive layer ensuring smooth transition between insulation and metallic shield.

- Metallic Shield: Copper tape or copper wire screen providing effective fault current path and electromagnetic shielding.

- Filler: Non-hygroscopic material maintaining cable’s circular shape and mechanical stability.

- Inner Sheath: PVC compound providing bedding for the armor.

- Armor: Double steel tape armor (Y22 designation) providing exceptional mechanical protection against crushing forces and rodent damage.

- Outer Sheath: Special flame-retardant PVC compound with low-smoke and halogen-free properties.

Performance Advantages

1. Superior Electrical Properties

ZR-YJV22-26/35kV cables deliver exceptional electrical performance through:

- High insulation resistance ensuring minimal leakage current

- Low dielectric loss factor (tan δ) reducing energy waste during transmission

- Stable dielectric constant across wide temperature ranges

- Excellent partial discharge resistance extending cable lifespan

- Consistent performance in both high and low temperature environments

2. Enhanced Thermal Performance

The cross-linked polyethylene insulation enables these cables to:

- Operate continuously at conductor temperatures up to 90°C

- Withstand short-circuit temperatures up to 250°C for brief periods

- Maintain structural integrity during thermal cycling

- Support higher current loads compared to conventional PVC-insulated cables

3. Outstanding Mechanical Strength

Engineered for durability in challenging environments:

- High tensile strength conductors resist stretching during installation and service

- Superior bending properties allow installation in confined spaces

- Excellent impact resistance protects against physical damage

- Steel tape armor provides protection against crushing forces and penetration

4. Enhanced Chemical and Environmental Resistance

- Resistant to oils, solvents, and various chemicals commonly found in industrial settings

- UV-resistant outer sheath suitable for outdoor installations

- Moisture-resistant construction prevents water ingress and associated failures

- Corrosion-resistant materials extend service life in harsh conditions

5. Advanced Safety Features

The “ZR” (flame retardant) designation indicates critical safety advantages:

- Low-smoke emission during combustion improves visibility for evacuation and firefighting

- Zero halogen content prevents production of toxic and corrosive gases during fire

- Self-extinguishing properties limit flame propagation

- Reduced fire load contributes to overall facility safety

Applications

ZR-YJV22-26/35kV cables are ideal for numerous demanding applications:

- Power Distribution Networks: Underground and overhead transmission systems

- Industrial Facilities: Manufacturing plants, refineries, and processing facilities

- Mining Operations: Surface and underground mining equipment power supply

- Renewable Energy Projects: Wind farms and solar power installations

- Transportation Infrastructure: Railway electrification and tunnel systems

- Commercial Buildings: High-rise structures requiring reliable power distribution

- Utility Substations: Interconnections between transformers and switchgear

Installation Guidelines

To ensure optimal performance and longevity:

- Pre-Installation Inspection: Check for physical damage before installation

- Bending Radius: Maintain minimum bending radius of 15× cable diameter during installation

- Pulling Tension: Limit pulling tension to manufacturer specifications (typically 25-30 N/mm² of conductor cross-section)

- Temperature Considerations: Avoid installation below 0°C ambient temperature

- Laying Pattern: Use trefoil formation for 3-core cables to minimize inductive losses

- Jointing & Termination: Use only compatible accessories and follow manufacturer procedures

- Testing: Perform insulation resistance and high-voltage withstand tests after installation

Comparison with Similar Cable Types

| Feature | ZR-YJV22-26/35kV | YJV22-26/35kV | ZR-YJV23-26/35kV |

|---|---|---|---|

| Flame Retardant | ✓ | ✗ | ✓ |

| Armor Type | Steel tape | Steel tape | Steel wire |

| Application | General purpose | Non-flame critical areas | Vertical installations |

| Impact Resistance | Good | Good | Excellent |

| Cost | Medium-high | Medium | High |

Frequently Asked Questions (FAQ)

Q: What does “ZR” designation mean in ZR-YJV22 cable?

A: “ZR” stands for “Flame Retardant” in Chinese classification, indicating the cable’s ability to resist flame propagation and limit fire spread.

Q: Can ZR-YJV22-26/35kV cables be installed directly underground?

A: Yes, the steel tape armor and robust outer sheath make these cables suitable for direct burial applications without additional protection.

Q: What is the expected service life of ZR-YJV22-26/35kV cables?

A: With proper installation and operation within specifications, these cables typically provide 30+ years of reliable service.

Q: How do I determine the appropriate conductor size for my application?

A: Conductor sizing should be based on load current, voltage drop limitations, short-circuit capacity, and installation conditions. Consult with a qualified electrical engineer for proper sizing.

Q: Are there environmental considerations when disposing of these cables?

A: The low-smoke zero-halogen (LSZH) variants are more environmentally friendly. Always follow local regulations for cable disposal and consider recycling options.