What Are BBTRZ and BTTRZ Cables?

BBTRZ Cable Overview

BBTRZ (Flexible Mineral Insulated Cable) is a high-performance fire-resistant cable designed to maintain circuit integrity during fire conditions. Also known as “flexible magnesium hydroxide mineral insulated non-flammable cable,” BBTRZ can withstand temperatures up to 950°C while maintaining electrical functionality for over three hours under 1,000V voltage stress.

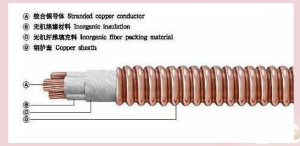

The cable features a multi-strand copper conductor wrapped with mica tape mineral insulation, fire-resistant mineral layers, and a corrosion-resistant outer sheath. Unlike traditional mineral-insulated cables, BBTRZ maintains flexibility while providing exceptional fire protection.

BTTRZ Cable Overview

BTTRZ cable represents an evolution of the BTTZ mineral-insulated cable design. The “R” in its designation indicates “flexibility” – a significant improvement over rigid mineral-insulated cables. BTTRZ maintains the excellent fire-resistant properties of traditional mineral-insulated cables while offering improved installation characteristics.

BTTRZ cables typically feature copper conductors surrounded by inorganic mineral insulation materials (often magnesium oxide or aluminum oxide compounds), enclosed within a continuous metal sheath that provides structural integrity and additional fire protection.

Key Structural Differences

The most fundamental distinction between these cable types lies in their construction:

BBTRZ Structure:

- Multi-strand flexible copper conductors

- Mineral-based insulation layers (typically mica tape)

- No continuous metal tube sheath

- Outer protective jacket made of fire-resistant materials

- Similar manufacturing process to conventional cables

BTTRZ Structure:

- Flexible copper conductors

- High-purity mineral insulation material

- Continuous welded copper sheath providing hermetic seal

- Optional outer protective jacket

- Specialized manufacturing process focused on maintaining the integrity of the mineral insulation

This structural difference – specifically the presence or absence of a continuous metal sheath – affects nearly every performance characteristic of these cables.

Performance Comparison

Fire Resistance

Both cable types excel in fire resistance, but through different mechanisms:

BBTRZ: Can withstand 950°C flame temperatures for over 3 hours while maintaining circuit integrity. The mineral insulation and fire-resistant outer layers provide protection, though the absence of a metal sheath makes it somewhat more vulnerable to direct flame impingement over extended periods.

BTTRZ: Offers superior long-term fire protection due to its hermetically sealed copper sheath, which prevents oxygen penetration and protects the mineral insulation. This design allows BTTRZ to maintain functionality in even the most severe fire conditions, often exceeding standard fire resistance requirements.

Electrical Performance

BBTRZ: Provides excellent electrical performance under normal conditions. However, its insulation resistance may be more affected by high humidity environments due to the absence of a sealed metal barrier. BBTRZ typically uses polyethylene-based materials in some components, which can affect long-term performance in extreme conditions.

BTTRZ: Delivers superior electrical performance in high-temperature scenarios due to the stability of its mineral insulation within the sealed copper sheath. The metal sheath also provides electromagnetic interference (EMI) shielding, making BTTRZ preferable for sensitive electronic applications.

Mechanical Properties

BBTRZ: Offers excellent flexibility with a bending radius typically around 6-8 times the cable diameter. The absence of a rigid metal sheath makes it easier to install in tight spaces and around corners.

BTTRZ: While flexible compared to traditional rigid mineral-insulated cables, BTTRZ has less flexibility than BBTRZ due to its metal sheath. However, it provides superior crush resistance and mechanical protection, making it more suitable for exposed installations or areas with potential physical damage risks.

Application Scenarios

Where to Use BBTRZ Cables

BBTRZ cables excel in applications where:

- High flexibility is required during installation

- Cost-effectiveness is a priority

- Moderate fire resistance requirements exist

- Humid environments are present (where its moisture resistance provides advantages)

- Industrial settings like mining operations and petrochemical facilities

- Retrofit projects where existing cable trays must accommodate new cables

Where to Use BTTRZ Cables

BTTRZ cables are preferable when:

- Maximum fire resistance is non-negotiable

- Critical infrastructure requires guaranteed circuit integrity

- EMI shielding is necessary for sensitive equipment

- Long-term reliability in harsh environments is essential

- High-rise buildings’ emergency systems

- Hospitals, data centers, and transportation infrastructure

- Nuclear facilities and other high-security installations

Cost Considerations

Initial investment in BTTRZ cable is typically 15-30% higher than BBTRZ due to the metal sheath and specialized manufacturing processes. However, when evaluating total cost of ownership, several factors must be considered:

- Installation costs: BBTRZ is generally easier and faster to install due to its superior flexibility

- Maintenance requirements: BTTRZ often requires less maintenance over its service life

- Lifespan: BTTRZ typically offers a longer service life, potentially 25-30 years versus 15-20 years for BBTRZ

- Business continuity value: The superior fire protection of BTTRZ may justify its higher initial cost in critical applications where downtime is extremely costly

Selection Guide: How to Choose Between BBTRZ and BTTRZ

When deciding between these cable types, consider these key questions:

- What are the fire safety requirements? Check local building codes and fire safety regulations. Critical infrastructure often mandates the superior protection of BTTRZ.

- What is the installation environment? Consider space constraints, bending requirements, and exposure to physical damage.

- What is the electrical load sensitivity? Applications with sensitive equipment benefit from BTTRZ’s EMI shielding properties.

- What is the budget versus lifecycle value? While BBTRZ has a lower initial cost, calculate the total cost of ownership including installation, maintenance, and expected service life.

- What are the environmental conditions? Humid, corrosive, or high-temperature environments may favor one cable type over the other.

Installation Best Practices

Regardless of which cable type you select, proper installation is critical for optimal performance:

- Follow manufacturer specifications for minimum bending radius

- Use appropriate termination kits designed specifically for mineral-insulated cables

- Ensure proper sealing of terminations to maintain fire-resistant properties

- Allow adequate space for thermal expansion in high-temperature applications

- Consider specialized training for installation teams unfamiliar with mineral-insulated cable systems