Understanding WDZ-YJY Cu/XLPE/LSZH Cable: Decoding the Technical Designation

What Each Component Means

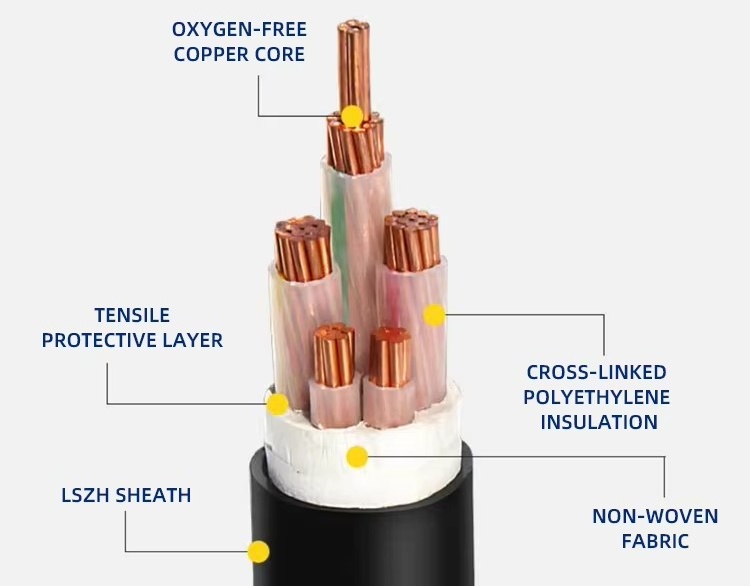

The designation “WDZ-YJY Cu/XLPE/LSZH” contains crucial information about this cable’s construction and capabilities:

- WDZ: Stands for “Wu-Di-Zu” in Chinese classification, indicating low smoke, low toxicity, and flame retardant properties

- YJY: Represents cross-linked polyethylene insulation with polyolefin sheathing

- Cu: Denotes copper conductors for optimal electrical performance

- XLPE: Cross-Linked Polyethylene insulation offering superior thermal and electrical properties

- LSZH: Low Smoke Zero Halogen compound for the outer sheath

This combination creates a cable that delivers exceptional electrical performance while dramatically reducing hazards during fire incidents—making it ideal for safety-critical applications where human evacuation time is precious.

Technical Specifications and Performance Characteristics

Electrical Performance

WDZ-YJY cables typically feature:

- Voltage ratings of 0.6/1kV for general power distribution

- Operating temperature range from -20°C to +90°C

- Short circuit temperature capability up to 250°C

- Excellent dielectric strength from XLPE insulation

- Low electrical losses even under heavy load conditions

Safety Specifications

The true value of WDZ-YJY cables lies in their safety performance:

- Smoke Density: Produces less than 40% smoke density during combustion (compared to 80%+ for standard PVC cables)

- Halogen Content: Virtually zero halogen emissions when exposed to fire

- Flame Propagation: Self-extinguishing properties with limited flame spread

- Toxicity Index: Significantly lower toxic gas emissions during combustion

- Dripping Resistance: No flaming droplets that could spread fire vertically

These specifications aren’t merely technical details—they translate directly to increased evacuation time and reduced equipment damage during fire emergencies.

Key Applications: Where WDZ-YJY Cables Deliver Maximum Value

Building Infrastructure

Modern high-rise buildings increasingly specify WDZ-YJY cables for:

- Emergency lighting circuits

- Fire alarm and suppression systems

- Elevator power supplies

- Hospital critical power systems

- Data center power distribution

- Public transportation terminals and stations

Industrial Applications

Manufacturing facilities rely on these cables for:

- Control room wiring

- Process control systems

- Clean room environments

- Food processing facilities (where toxic emissions could contaminate products)

- Offshore platforms and marine vessels

Public Infrastructure Projects

Municipal projects benefit from WDZ-YJY cables in:

- Underground rail systems and subway tunnels

- Airport terminal electrical systems

- Educational institutions and libraries

- Government buildings and emergency response facilities

- Sports arenas and entertainment venues

Why WDZ-YJY Outperforms Traditional Cable Options

Compared to PVC-Insulated Cables

While PVC cables remain common due to lower initial costs, WDZ-YJY cables offer compelling advantages:

- Safety: PVC releases hydrochloric acid and dense black smoke when burned

- Corrosion Prevention: LSZH materials won’t corrode sensitive electronic equipment during fires

- Regulatory Compliance: Meets increasingly stringent building codes worldwide

- Long-term Value: Reduced insurance premiums and lower liability exposure

Compared to Other Flame-Retardant Options

WDZ-YJY stands apart from other fire-resistant cables by addressing all aspects of fire safety:

- Not just flame resistance, but smoke density control

- Not just heat resistance, but toxicity reduction

- Not just fire performance, but maintaining circuit integrity longer

Installation Best Practices for WDZ-YJY Cables

Handling and Preparation

- Store cables in dry conditions away from direct sunlight

- Allow cables to acclimate to installation temperature before handling

- Use appropriate pulling grips to prevent conductor damage

- Maintain minimum bending radius of 15× cable diameter during installation

Termination Considerations

- Use connectors specifically rated for XLPE-insulated conductors

- Ensure proper torque specifications are followed for all connections

- Maintain separation between power and data cables to prevent interference

- Document all installations with proper labeling at termination points

Regulatory Compliance

WDZ-YJY cables typically comply with international standards including:

- IEC 60502 (International Electrotechnical Commission)

- BS 6724 (British Standards)

- EN 50575 (European fire classification)

- GB/T 12706 (Chinese national standards)

Always verify local code requirements before installation, as fire safety regulations vary by jurisdiction.

Total Cost of Ownership: Beyond Initial Purchase Price

While WDZ-YJY cables may carry a 15-30% premium over standard cables, their total value proposition includes:

- Insurance Benefits: Many insurers offer reduced premiums for LSZH cable installations

- Maintenance Savings: XLPE insulation provides longer service life in demanding environments

- Business Continuity: Reduced downtime following minor fire incidents

- Asset Protection: Prevents secondary damage to electronics from corrosive gases

- Reputation Management: Demonstrates commitment to occupant safety and environmental responsibility

Future-Proofing Your Electrical Infrastructure

As building codes worldwide increasingly mandate LSZH cables in public and high-occupancy spaces, installing WDZ-YJY cables today positions your facility for tomorrow’s requirements. With many municipalities accelerating adoption of stricter fire safety standards following high-profile incidents, this cable type represents not just a technical specification but a strategic investment in long-term compliance.

Selecting the Right WDZ-YJY Cable Supplier

When sourcing these critical components:

- Verify manufacturer certifications and testing documentation

- Request independent fire test reports (not just manufacturer claims)

- Confirm conductor purity meets IACS standards

- Evaluate supplier technical support capabilities

- Check warranty terms specific to fire performance characteristics

Frequently Asked Questions About WDZ-YJY Cables

Q: Can WDZ-YJY cables be installed in the same conduits as data cables?

A: Yes. The low electromagnetic interference characteristics of WDZ-YJY cables make them suitable for shared pathways with data and communication cables. Their stable dielectric properties minimize signal interference, unlike some older cable types.

Q: How does the price of WDZ-YJY compare to similar safety-rated cables?

A: WDZ-YJY typically costs 30-50% more than standard PVC cables but 40-60% less than mineral-insulated (MI) cables. The price premium over PVC is offset by reduced installation costs compared to MI cables and superior flexibility.

Q: Are there armored versions of WDZ-YJY available for direct burial?

A: Yes. The WDZ-YJY22 variant includes steel tape armor between the insulation and LSZH sheath, making it suitable for direct burial applications and areas requiring mechanical protection. This maintains the low-smoke zero-halogen properties while enhancing durability.

Q: What testing certifications should I look for when purchasing WDZ-YJY cables?

A: Reputable WDZ-YJY cables should carry certifications including IEC 60502-1 (power cables), IEC 60332-1 & -3 (flame retardance), IEC 61034 (smoke emission), and IEC 60754 (halogen acid gas emission). Project specifications may also require regional certifications like UL, CSA, or CPR classification.