When harsh environments threaten electrical connections, waterproof rubber cable stands as the frontline defense against moisture, chemicals, and physical damage. This comprehensive guide explores why these specialized cables have become indispensable across industries—from marine operations to underground mining—and how to select the perfect solution for your demanding applications.

What Makes Rubber Cables Waterproof?

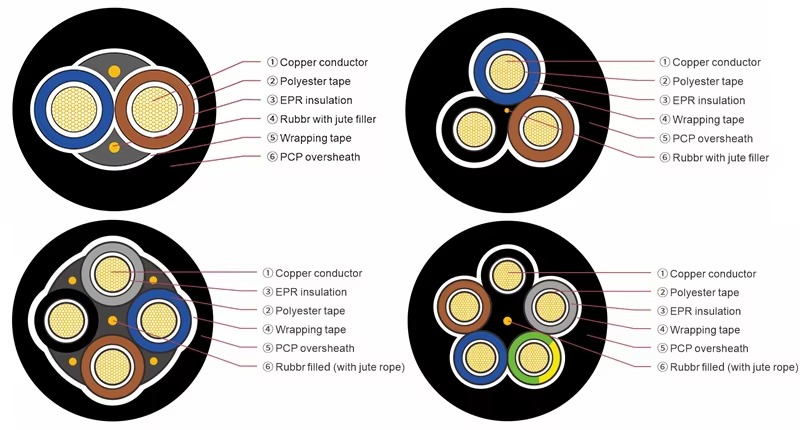

Waterproof rubber cables utilize specialized elastomer compounds that create a continuous protective barrier around conductors. Unlike standard PVC insulation that can degrade when exposed to moisture, quality rubber compounds feature:

- Molecular water resistance: Rubber polymers naturally repel water penetration

- Seamless extrusion: Manufacturing processes create uniform, pinhole-free insulation

- Compression sealing: Cable glands and connectors compress against rubber’s elastic properties

- Self-healing characteristics: Minor surface abrasions typically won’t compromise waterproofing

The most effective waterproof rubber cables employ compounds like EPDM (Ethylene Propylene Diene Monomer), neoprene, or specialized silicone blends engineered specifically for extreme environmental resistance.

Top Industries Relying on Waterproof Rubber Cables

Marine & Offshore Applications

Ships, offshore platforms, and port facilities depend on waterproof rubber cables that withstand constant saltwater exposure. These cables power navigation systems, deck lighting, winches, and communication equipment where failure isn’t an option.

Mining & Tunneling Operations

Underground mining environments subject cables to water immersion, mud, chemicals, and physical abuse. Waterproof rubber cables deliver reliable power and signal transmission for ventilation systems, pumps, lighting arrays, and monitoring equipment.

Renewable Energy Installations

Solar farms and wind turbines utilize waterproof rubber cables for connections exposed to weather extremes. These cables maintain performance despite UV radiation, temperature fluctuations, and precipitation.

Industrial Food Processing

Food production facilities require cables that survive high-pressure washdowns with cleaning chemicals. Waterproof rubber cables with FDA-approved compounds ensure safety compliance while maintaining electrical integrity.

Technical Specifications That Matter

When evaluating waterproof rubber cables, these specifications determine real-world performance:

| Specification | Importance | Typical Range |

|---|---|---|

| IP Rating | Water/dust protection level | IP68 (continuous immersion) |

| Temperature Range | Operational limits | -40°C to +90°C (varies by compound) |

| Voltage Rating | Electrical capacity | 300/500V to 1.8/3kV |

| Flexibility | Bend radius & movement tolerance | 6-8× cable diameter |

| Oil/Chemical Resistance | Environmental durability | UL Oil Res I/II or custom testing |

Pro Tip: For submersion applications exceeding 10 meters depth, verify pressure testing certifications specific to your operational depth.

Selecting the Right Waterproof Rubber Cable: 5 Critical Factors

1. Environmental Exposure Assessment

Document all environmental factors: water type (fresh/salt), chemical exposure, temperature extremes, UV radiation, and physical hazards. This determines the appropriate rubber compound.

2. Current Carrying Capacity Requirements

Calculate total connected load plus 25% safety margin. Remember that water immersion affects heat dissipation—derate capacity by 15% for continuously submerged applications.

3. Flexibility vs. Durability Balance

High-flexibility rubber compounds sacrifice some abrasion resistance. For fixed installations, prioritize durability; for robotic or moving equipment, select high-flex variants.

4. Certification Compliance

Verify industry-specific certifications:

- Marine: DNV-GL, ABS, LR approvals

- Mining: MSHA, IECEx certifications

- Food Industry: FDA, EU 10/2011 compliance

- General: UL, CE, RoHS documentation

5. Connector Compatibility

Waterproof performance fails at connection points. Ensure your selected cable pairs with IP68-rated connectors designed specifically for rubber cable jacket materials.

Installation Best Practices for Maximum Longevity

Even the highest-quality waterproof rubber cable fails with improper installation. Follow these field-tested guidelines:

- Avoid sharp bends: Maintain minimum bend radius during installation

- Secure properly: Use non-abrasive cable ties rated for outdoor/wet environments

- Strain relief: Implement proper strain relief at connection points

- Temperature acclimation: Allow cables to acclimate to ambient temperature before installation in extreme environments

- Joint protection: Use heat-shrink marine-grade sealants for any field splices

“Many cable failures occur at termination points,” notes electrical engineer Maria Chen. “Investing in proper waterproof connectors costs less than emergency repairs in inaccessible locations.”

Maintenance Protocol for Extended Service Life

Implement these maintenance practices to maximize cable lifespan:

- Quarterly visual inspections: Check for jacket cracking, abrasion, or swelling

- Annual insulation resistance testing: Measure with megohmmeter at 500V DC

- Connection point verification: Ensure seals remain compressed and intact

- Cleaning protocol: Use manufacturer-approved cleaning solutions only

- Documentation: Record installation dates and inspection findings for predictive replacement planning

Safety Considerations You Cannot Ignore

Working with waterproof rubber cables in wet environments demands extra precautions:

- Always de-energize circuits before inspection or maintenance

- Use GFCI protection for all temporary installations

- Verify cable ground continuity before energizing

- Implement lockout/tagout procedures in industrial settings

- Train personnel on specific hazards of wet-environment electrical work

Never compromise on quality for critical applications—a $50 cable failure can trigger $50,000 in equipment damage or safety incidents.

Frequently Asked Questions

Q: How deep can IP68-rated rubber cables operate underwater?

A: Standard IP68 cables withstand continuous immersion at 1-3 meters depth. For greater depths (up to 100m+), specialized submarine cables with additional armor and pressure testing are required.

Q: Can I repair damaged waterproof rubber cable jacket in the field?

A: Minor abrasions on non-critical sections can be repaired with self-amalgamating tape rated for underwater use. However, conductor exposure or significant damage requires professional repair or replacement.

Q: How long do quality waterproof rubber cables last in constant immersion?

A: Premium rubber cables in stable environments typically provide 10-15 years of service life when properly installed. Factors like temperature cycling, chemical exposure, and mechanical stress can reduce this significantly.

Q: Are rubber cables more environmentally friendly than PVC alternatives?

A: Modern rubber compounds often contain fewer plasticizers than PVC and better resist leaching in aquatic environments. However, recycling infrastructure for rubber cables remains limited compared to PVC options.

Q: What’s the temperature limit for standard waterproof rubber cables?

A: General-purpose EPDM rubber cables typically handle -40°C to +90°C. Specialized silicone variants extend this range to -60°C to +180°C for extreme applications.