Understanding and Preventing Broken Conductors in Drag Chain Cables

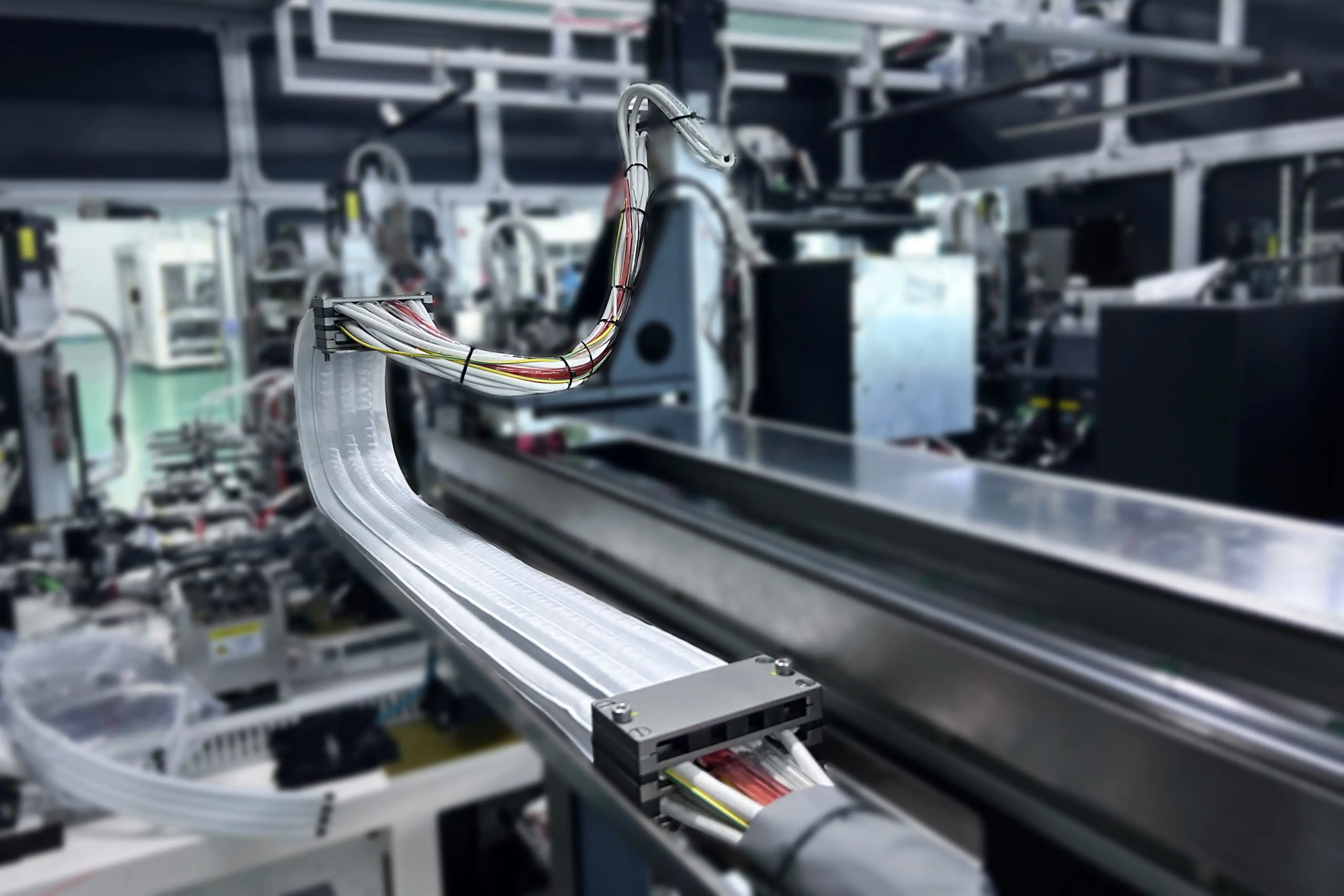

Drag chain cables—also known as energy chain or cable carrier cables—are essential components in dynamic automation systems, where they supply power, data, or signals to moving machinery such as robotic arms, CNC machines, and automated guided vehicles (AGVs). Despite their robust design, these cables are prone to failure over time, with one of the most common issues being broken conductors (or “core breaks”). Understanding the root causes and implementing preventive measures can significantly extend cable life and reduce costly downtime.

Common Causes of Broken Conductors

- Excessive Bending Stress

Drag chain cables undergo repeated bending during operation. If the bend radius is too tight—below the manufacturer’s recommended minimum—the internal conductors experience high mechanical stress, leading to metal fatigue and eventual breakage. - Improper Cable Construction

Standard fixed-installation cables are not designed for continuous flexing. Using non-flexing or semi-flexing cables in dynamic applications accelerates conductor wear due to inadequate strand architecture and insufficient flexibility. - Poor Cable Management Inside the Drag Chain

Overfilling the drag chain, mixing cable types without proper separation, or allowing cables to twist or rub against each other creates uneven stress distribution and abrasion, which can damage insulation and lead to conductor fractures. - High Acceleration and Jerky Movements

Rapid starts/stops or high-speed motion generate inertial forces that cause internal conductors to shift violently within the jacket, especially if the cable lacks proper strain relief or tensile members. - Inadequate Torsional Resistance

In applications involving rotational movement (e.g., 6-axis robots), torsional stress can cause conductors to unwind or snap if the cable isn’t specifically designed for torsional flexibility. - Environmental Factors

Exposure to extreme temperatures, chemicals, moisture, or UV radiation can degrade jacket and insulation materials, reducing overall cable resilience and making conductors more vulnerable to mechanical failure.

How to Prevent Broken Conductors

- Use Purpose-Built Continuous-Flex Cables

Always select cables explicitly rated for dynamic applications. These feature finely stranded conductors (often Class 6 per IEC 60228), optimized lay lengths, and specialized jacket materials like PUR or TPE for enhanced flexibility and durability. - Respect Minimum Bend Radius

Ensure the drag chain’s bend radius meets or exceeds the cable manufacturer’s specification—typically 7.5× to 12.5× the cable diameter for continuous-flex applications. - Optimize Cable Layout in the Drag Chain

- Fill the drag chain to only 70–80% capacity to allow free movement.

- Separate power and signal cables using dividers to prevent crosstalk and mechanical interference.

- Secure cables at both ends with proper clamps to avoid internal movement (“corkscrewing”).

- Choose Cables with Central Strength Members

High-quality drag chain cables often include a central anti-compression element (e.g., a fiberglass rod or aramid yarn) that stabilizes conductor bundles and absorbs tensile loads. - Match Cable Type to Motion Profile

For pure linear motion, use standard continuous-flex cables. For rotational or multi-axis movement, select torsion-rated cables tested for millions of cycles under ±180°/m or higher torsion angles. - Conduct Regular Maintenance and Inspection

Periodically check for signs of wear—such as jacket cracking, swelling, or stiff sections—and replace cables before catastrophic failure occurs. Implement predictive maintenance using condition monitoring where possible. - Work with Reputable Suppliers

Partner with cable manufacturers who provide test data (e.g., UL-certified flex life ratings, ISO-compliant cycle testing) and application engineering support.

The above is the knowledge we have provided for you about drag chain cables. If you have any further technical questions or need to purchase related products, please feel free to contact us.