Description

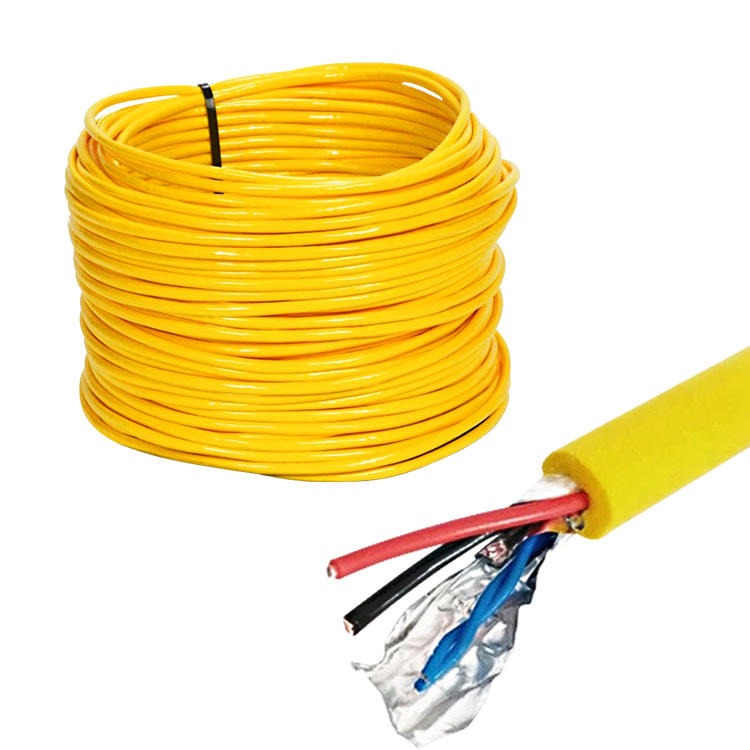

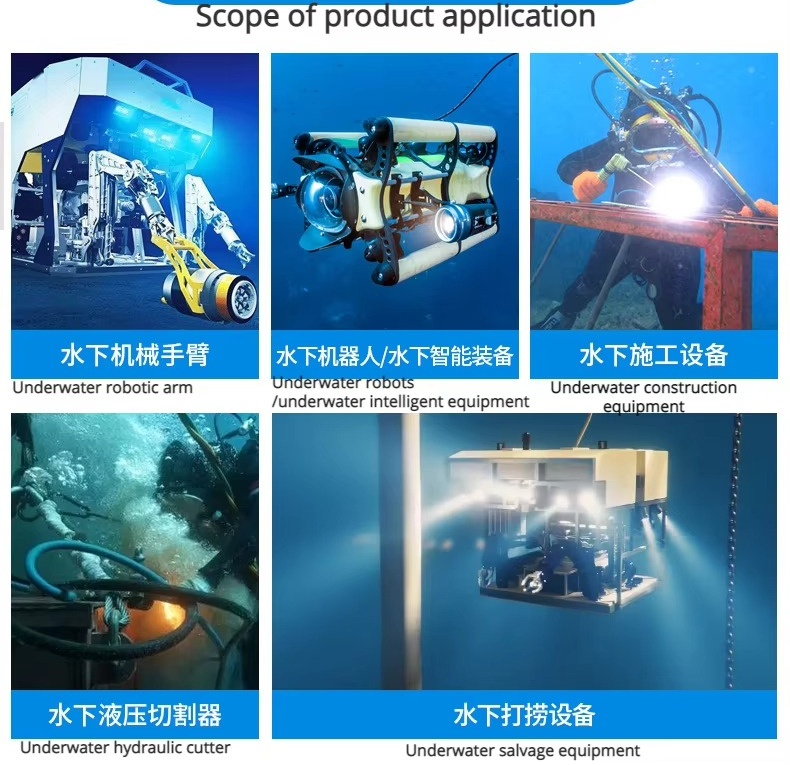

1. Application: This product is mainly used in underwater robots, underwater salvage equipment, underwater construction equipment, underwater robotic arms, and underwater

Mechanical equipment such as hydraulic cutters that operate in harsh underwater environments can be dragged and retracted with the equipment in the water.

2. Product Description

◆ The conductor uses multiple strands of finely twisted tinned copper wire

◆ Insulation: TPE or polyolefin material

◆ Number of cable cores: 2-4 cores

◆ Multi core cable, filled with Kevlar bulletproof wire

◆ Inner sheath: Low viscosity elastomer

◆ Outer sheath: High strength foam polyurethane material

The rated voltage Uo/U is 300/300V

Voltage withstand test 1500V 50-60Hz for 1 minute

The long-term allowable working temperature of this cable is -50 ∞ 80 ° C

Water pressure resistance strength: Longitudinal water pres

3. Typical specifications (for more other specifications or special customized products, please feel free to inquire)

| Conductor gauge | Insulation wire diameter(mm) | Fill reinforcement | Sheath OD ( mm) | Tensile resistance | Maximum conductor resistance at 20 ℃(Ω/km) |

| 28AWG | 0.7 | Kevlar | 3.6-3.7 | 100kgf+ | 205 |

| 27AWG | 0.9 | Kevlar | 4.0-4.2 | 100kgf+ | 170 |

| 24AWG | 1.1 | Kevlar | 5.0-5.2 | 100kgf+ | 85 |

| 20AWG | 1.6 | Kevlar | 8.0-8.5 | 100kgf+ | 35 |

| 4coreX(19*0.10) | 1.5 | Kevlar | 8.0 | 200kgf+ | 79 |

| 4coreX(19*0.16) | 1.8 | Kevlar | 10.5 | 300kgf+ | 43 |

| 4coreX(19*0.20) | 2.0 | Kevlar | 13.0 | 600kgf+ | 26 |

| 4coreX2X(7*0.16) | 0.9 | Kevlar | 7.0-8.0 | 100kgf+ | 79 |

Features of ROV waterproof cable

1.A single cable can integrate power supply, signals, video, etc., and can simultaneously transmit video signals, power signals, and control signals. Network signals, etc., and they are convenient to set up.

2. The core wire adopts multi-strand oxygen-free copper wire/tin-plated copper wire, which can enhance the bending resistance of the core wire.

3.The addition of tensile components enhances the tensile capacity and service life of the cables, and improves the utilization rate of the cables. The interior is filled with Kevlar/polyester yarn, and the exterior is Kevlar woven mesh for tensile resistance.

4. The selection of imported high-flexibility waterproof sheath materials ensures that the cable does not break or crack during high-speed movement, and also has waterproof and tensile resistance properties, greatly improving the utilization efficiency of the cable.

——Our Feature——

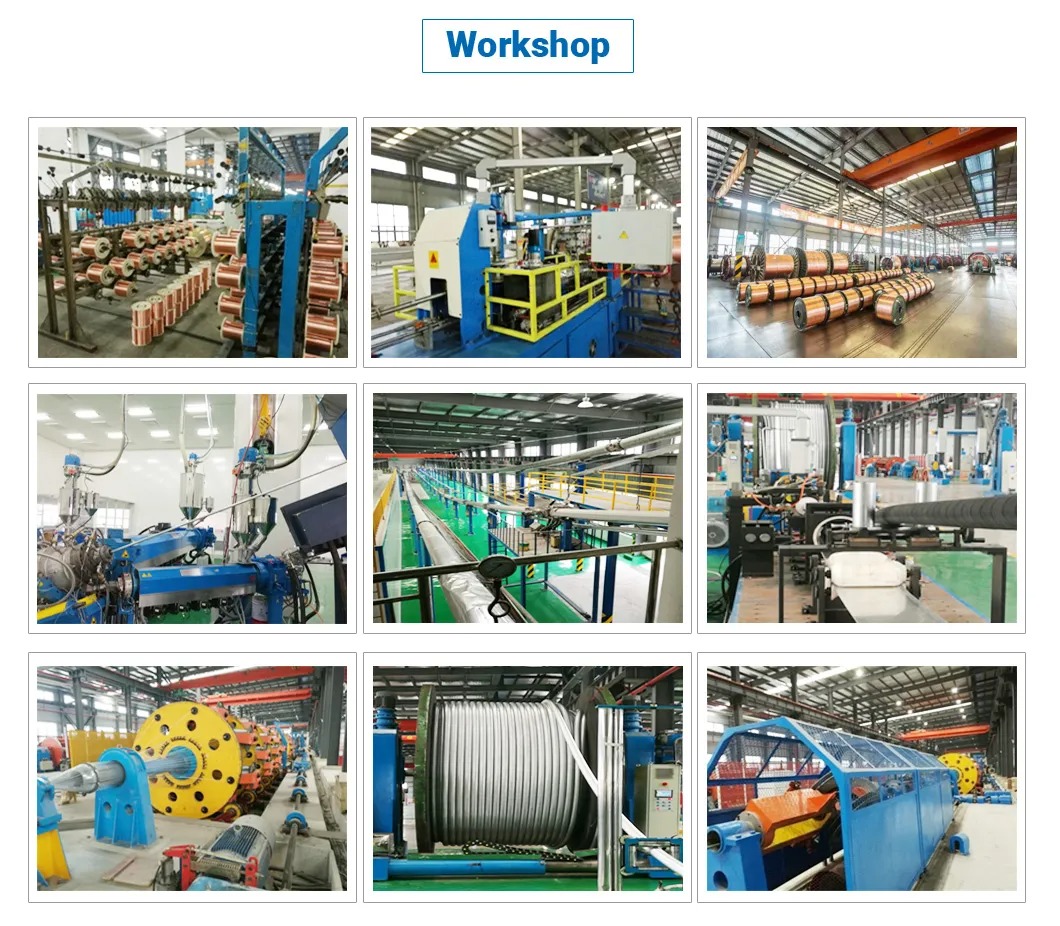

1.Imported equipment with experienced technical team

We have three plant and has 3048 employees which have 206 engineers. Plant has a series of imported production lines including Niehoff copper drawing lines, Troster Germany and Maillefer Finland 500KV VCV lines, stranding machine from Pourtier France, SKET Germany, Caballe Spain, 220KV and 35KV production line plus SIKORA X – RAY 8000 on-line eccentricity measuring unit from Germany

2.Complete certification system

We have gotten ISO 9001, ISO 14001, OHSAS 18001. Plant passed TUV, VDE, UL, CE, SAA, BS etc. certificate.

3.Perfect Production system

Our products cover LV power cable, MV power cable, HV&EHV power cable, ABC cables, ACSR/AAC/AAAC/ACAR/OPGW ,submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, Lan cable, coaxial cable etc.

4.Perfect Sales service system

We can offer the OEM/ODM service, Multiple products, Skilled Export sale engineer team, Reasonable price, Reliable quality, Friendly service.