U1000 R2V 0.6/1kV Power Cable

Reply Quickly

7 Days Fast Delivery

High Praise Rate

Zero Complaints & incidents

The U1000 R2V series are low voltage power cables designed for energy distribution in industrial and commercial applications. These robust cables feature cross-linked polyethylene (XLPE) insulation and PVC outer sheath, providing excellent electrical performance and mechanical protection. Suitable for a wide range of installations including underground networks, industrial facilities, building wiring, and outdoor applications.

Technical Specifications

Electrical Characteristics

- Rated Voltage (U₀/U): 600/1000V AC

- Maximum System Voltage (Um): 1200V AC

- Test Voltage: 3500-4000V AC

- Conductor Maximum Operating Temperature: 90°C

- Short Circuit Maximum Temperature: 250°C (max. 5 seconds)

- Minimum Installation Temperature: -10°C

- Minimum Operating Temperature (without mechanical stress): -25°C

Construction Details

- Conductor:

- Single core: Rigid copper conductor (Class 1) for sections ≤ 4mm²

- Multi-core: Stranded circular compacted copper conductors (Class 2) for sections > 4mm²

- Compliant with IEC 60228, BS EN 60228:2005 and UNE 60228

- Insulation: Cross-linked polyethylene (XLPE), type DIX-3 or equivalent

- Provides superior electrical properties and higher current carrying capacity compared to PVC insulation

- Sheath: Special PVC compound (type DMV-18 or equivalent)

- Excellent resistance to sunlight, weather conditions, and chemical agents

- Flame retardant properties according to international standards

Fire Performance

- CPR Classification: Eca (Euroclass E)

- Flame Propagation: Non-flame propagating according to NF 32070, UNE-EN 60332-1-2, EN 60332-1-2 and IEC 60332-1-2

Application Areas

These versatile cables are recommended for:

- Underground networks for low voltage distribution

- Service connections (underground supply networks)

- Industrial installations and equipment connections

- Building wiring systems and riser columns

- Outdoor lighting installations

- Areas with high operating temperatures

- Environments requiring high resistance to solar radiation and atmospheric agents

- Fixed installations in cable ducts, trays, or directly fixed to walls

- Walkways and empty constructions (without additional mechanical protection)

- Underground installations with appropriate mechanical protection (slabs, tiles, or bricks)

Note: Not recommended for installation in ground flooded for more than two months per year. When used in explosive risk areas with appropriate mechanical protection, current carrying capacity must be reduced by 15%.

Installation Recommendations

Bending Radius

- Single core cables: 6 times the cable diameter

- Multi-core cables: 8 times the cable diameter

Maximum Pulling Stress

- 5 kg/mm² of copper cross section

Current Carrying Capacity

Current ratings depend on:

- Number of cores

- Cross-sectional area

- Installation method (free air or buried)

- Ambient temperature

- Grouping with other cables

Note: Correction factors must be applied in case of high ambient temperatures or when cables are installed in groups.

Core Identification & Color Coding

Single Core Cables

- Black sheath (or other colors upon request)

Multi-Core Cables

Two cores: Blue-Brown

Three cores:

- Type A (1.5/2.5mm²): Brown-Black-Blue

- Type B (≥4mm²): Brown-Black-Grey or Green/Yellow-Blue-Brown

Four cores: Blue-Brown-Black-Grey (Green/Yellow instead of Blue for earth conductor)

Five cores: Blue-Brown-Black-Grey-Green/Yellow

Cables with more than five cores: Black sheath with colored strip identification

Standards & Certifications

The U1000 R2V cables comply with the following international and European standards:

- IEC 60502-1

- HD 603 S1

- UNE 21123

- NF C 32-321:2022

- EN 50575:2014 + A1:2016 (CPR)

- HD 308 S2/S3 (color coding)

- NF C 15-100

- RoHS 3 Directive compliance

Technical Data Tables

Single Core Cables

| Cross-section (mm²) | Max. outer diameter (mm) | Weight (kg/km) | Resistance at 20°C (Ω/km) | Current rating in air (A) | Current rating buried (A) |

|---|---|---|---|---|---|

| 1.5 | 6.4-6.6 | 45-50 | 12.1 | 24 | 31 |

| 2.5 | 7.0 | 55 | 7.41 | 33 | 41 |

| 4 | 7.6 | 75-80 | 4.61 | 45 | 59 |

| 6 | 8.2 | 100 | 3.08 | 58 | 74 |

| 10 | 9.2 | 140-145 | 1.83 | 80 | 101 |

| 16 | 10.5 | 205 | 1.15 | 107 | 128 |

| 25 | 12.5 | 290-315 | 0.727 | 138 | 144 |

| 35 | 13.5 | 390-400 | 0.524 | 169 | 174 |

| 50 | 15.0 | 510-530 | 0.387 | 207 | 206 |

| 70 | 17.0 | 720-725 | 0.268 | 268 | 254 |

| 95 | 19.0 | 970-985 | 0.193 | 328 | 301 |

| 120 | 21.0 | 1210-1260 | 0.153 | 382 | 343 |

| 150 | 23.0 | 1480-1520 | 0.124 | 441 | 387 |

| 185 | 25.5 | 1835-1940 | 0.0991 | 506 | 434 |

| 240 | 28.5 | 2540-2310 | 0.0754 | 599 | 501 |

| 300 | 31.0 | 2945-3200 | 0.0601 | 693 | 565 |

| 400 | 34.2 | 3931 | 0.0470 | 825 | 662 |

| 500 | 38.0 | 4890-5020 | 0.0366 | 946 | 750 |

| 630 | 44.0 | 5324-6158 | 0.0283-0.0286 | 1083 | 843 |

Note: Values may vary slightly between manufacturers. Comprehensive tables for multi-core configurations (2-core, 3-core, 4-core, 5-core and more) with various cross-sections available upon request.

Product Advantages

- Higher current capacity due to XLPE insulation compared to PVC insulated cables of the same cross-section

- Excellent thermal stability with maximum operating temperature of 90°C

- Superior mechanical properties providing durability in harsh environments

- Good resistance to oils, chemicals and UV radiation

- Flame retardant sheath compound limits fire propagation

- Wide operating temperature range from -25°C to 90°C

- Flexible installation options for both indoor and outdoor applications

Handling & Storage

- Store in dry conditions, protected from direct sunlight

- Avoid sharp bends during handling and installation

- Follow local electrical regulations and installation guidelines

- Use appropriate cable accessories (glands, connectors) for termination

Note: The information contained in this document is for informational purposes only and does not constitute a contractual commitment. Technical specifications may be modified without prior notice as part of continuous improvement processes. Always verify the latest specifications with the manufacturer before installation.

——Our Feature——

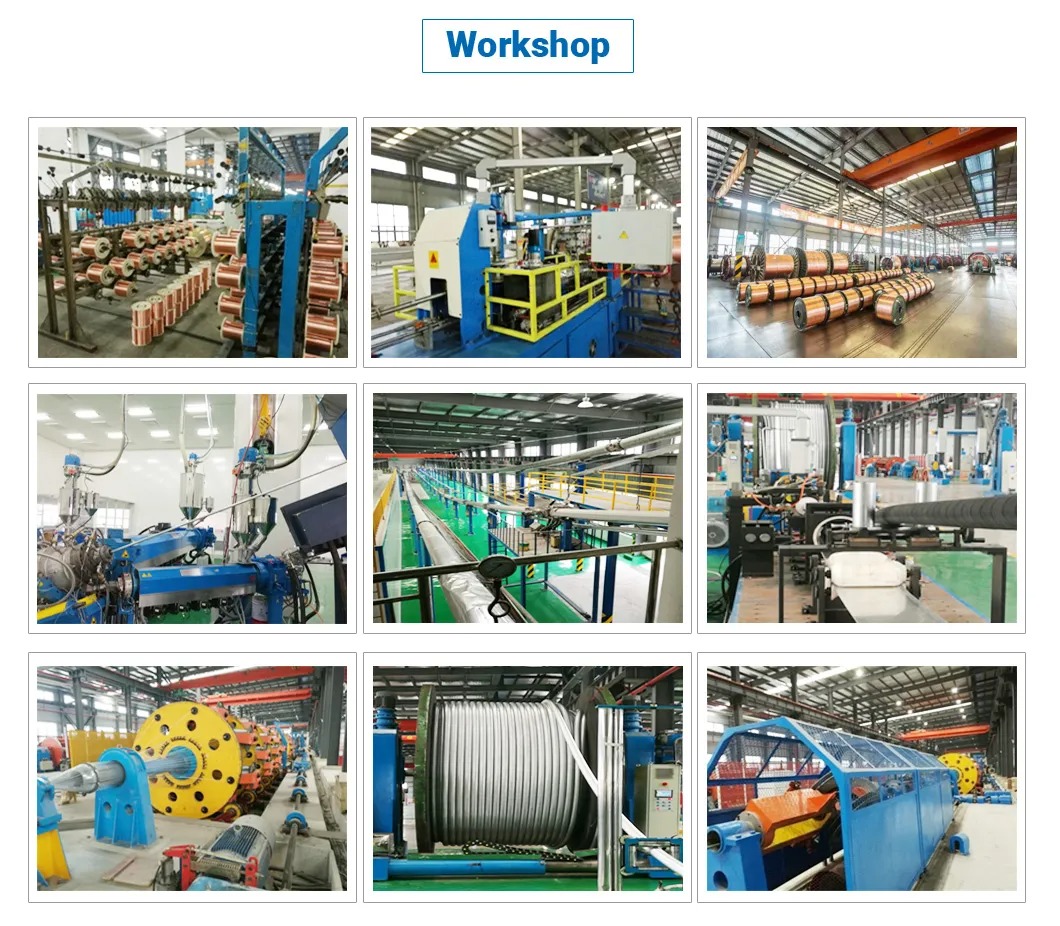

1.Imported equipment with experienced technical team

We have three plant and has 3048 employees which have 206 engineers. Plant has a series of imported production lines including Niehoff copper drawing lines, Troster Germany and Maillefer Finland 500KV VCV lines, stranding machine from Pourtier France, SKET Germany, Caballe Spain, 220KV and 35KV production line plus SIKORA X – RAY 8000 on-line eccentricity measuring unit from Germany

2.Complete certification system

We have gotten ISO 9001, ISO 14001, OHSAS 18001. Plant passed TUV, VDE, UL, CE, SAA, BS etc. certificate.

3.Perfect Production system

Our products cover LV power cable, MV power cable, HV&EHV power cable, ABC cables, ACSR/AAC/AAAC/ACAR/OPGW ,submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, Lan cable, coaxial cable etc.

4.Perfect Sales service system

We can offer the OEM/ODM service, Multiple products, Skilled Export sale engineer team, Reasonable price, Reliable quality, Friendly service.