——Our Feature——

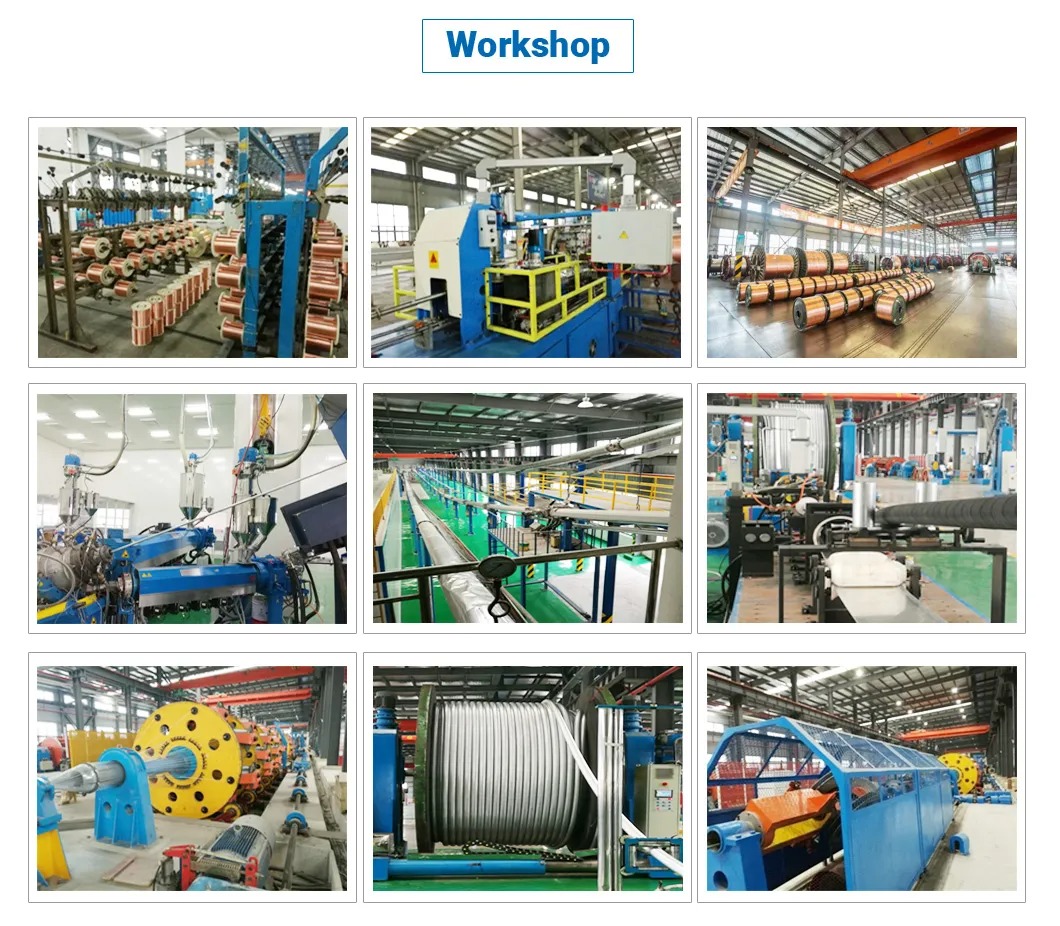

1.Imported equipment with experienced technical team

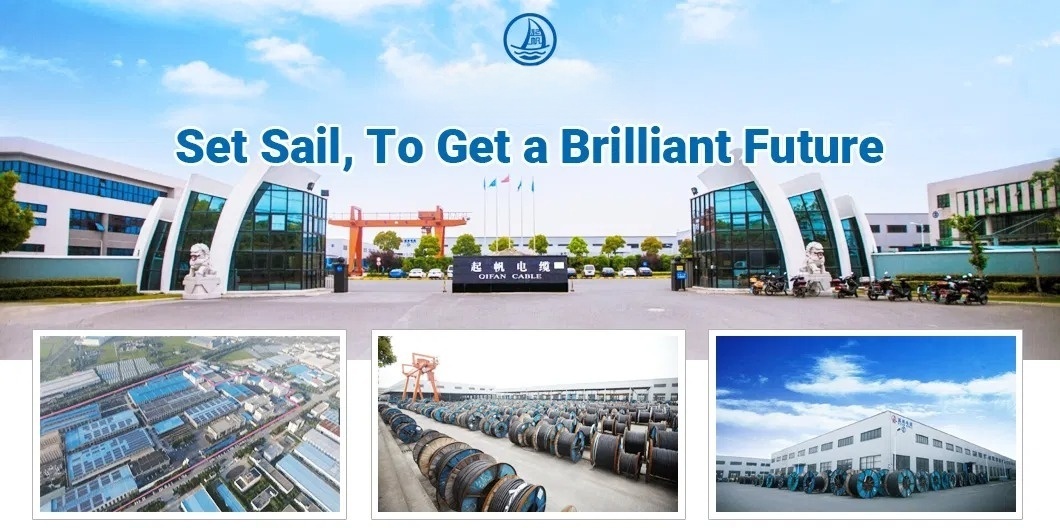

We have three plant and has 3048 employees which have 206 engineers. Plant has a series of imported production lines including Niehoff copper drawing lines, Troster Germany and Maillefer Finland 500KV VCV lines, stranding machine from Pourtier France, SKET Germany, Caballe Spain, 220KV and 35KV production line plus SIKORA X – RAY 8000 on-line eccentricity measuring unit from Germany

2.Complete certification system

We have gotten ISO 9001, ISO 14001, OHSAS 18001. Plant passed TUV, VDE, UL, CE, SAA, BS etc. certificate.

3.Perfect Production system

Our products cover LV power cable, MV power cable, HV&EHV power cable, ABC cables, ACSR/AAC/AAAC/ACAR/OPGW ,submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, Lan cable, coaxial cable etc.

4.Perfect Sales service system

We can offer the OEM/ODM service, Multiple products, Skilled Export sale engineer team, Reasonable price, Reliable quality, Friendly service.