NYY cables are an economical solution for power and control wiring applications where mechanical protection is not required. Originating in Germany, these cables have gained popularity worldwide as a versatile alternative to armored cables like SWA (Steel Wire Armoured) in appropriate applications. The absence of armor offers several benefits including cost savings, reduced weight, and smaller cable diameter while maintaining excellent electrical performance.

Applications

NYY power cables are designed for fixed installations in various environments:

- Cable ducts

- Power stations

- Distribution boards

- Industrial applications and subscriber networks

- Brickwork and concrete

- Open air installations

- Underground installations

- Water applications

- Indoor installations

These cables provide a robust solution for energy supply where no mechanical damage is expected.

Construction

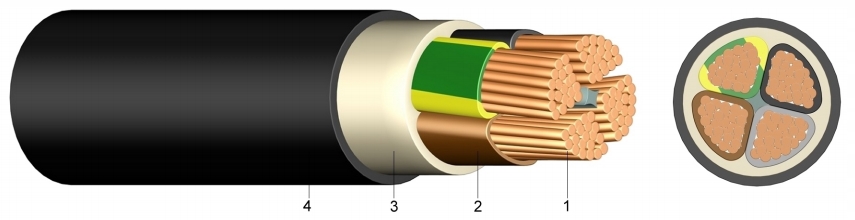

Standard NYY Cable:

- 1 ….. solid (RE) or stranded (RM/SM) bare copper

- 2 ….. core insulation of polyvinylchloride (PVC)

- 3 ….. PVC core covering or taping

- 4 ….. outer sheath of polyvinylchloride (PVC), black, UV-resistant

Variants:

- NYY-J/O: Class 1 solid copper or Class 2 stranded copper conductor

- NYCWY: Includes concentric conductor with waveconal outer conductor (copper wire and counter spiral copper tape)

- NYCY: Features concentric conductor of copper wires and copper tape

- NAYY: Aluminum conductor versions available

Technical Data

- Nominal voltage Uo/U: 600/1000 V

- Test voltage AC: 4000 V

- Temperature range:

- In motion: -5°C to +70°C

- Fixed installation: -20°C to +70°C

- Bending radius:

- Single-core: 15 × diameter

- Multi-core: 12 × diameter

- Short circuit temperature on core (max. 5 sec.):

- ≤300mm²: 160°C

-

300mm²: 140°C

- Flammability standard: EN 60332-1-2

Current Carrying Capacity Tables

Single Core Cables

| Cross Section (mm²) | Copper Figure (kg/km) | Overall Diameter (mm) | Weight (kg/km) | Current Capacity Ground (A) | Current Capacity Air (A) |

|---|---|---|---|---|---|

| 1 x 4 RE | 38.4 | 8 | 120 | 50 | 37 |

| 1 x 6 RE | 57.6 | 9 | 131 | 62 | 47 |

| 1 x 10 RE | 96.0 | 10 | 171 | 83 | 64 |

| 1 x 16 RE | 153.6 | 11 | 233 | 107 | 84 |

| 1 x 25 RM | 240.0 | 12 | 370 | 138 | 114 |

| (Table continues with additional sizes up to 1 x 630 RM) |

Multi-Core Cables (Selected Examples)

| Configuration | Cross Section (mm²) | Copper Figure (kg/km) | Overall Diameter (mm) | Weight (kg/km) | Current Capacity Ground (A) | Current Capacity Air (A) |

|---|---|---|---|---|---|---|

| 3 x 1.5 RE | – | 43.2 | 13 | 244 | 27 | 20 |

| 3 x 2.5 RE | – | 72.0 | 14 | 294 | 36 | 25 |

| 4 x 16 RM | – | 614.4 | 22 | 1,072 | 102 | 79 |

| 4 x 25 RM | – | 960.0 | 27 | 1,632 | 133 | 106 |

| 5 x 10 RM | – | 480.0 | 21 | 921 | * | * |

Note: Current carrying capacity for 5+ core cables depends on the number of loaded cores (see DIN VDE 0276-627)

Standards Compliance

- DIN VDE 0276-603

- HD 603 S1:1994+ A2:2003

- DIN EN 60228 class 1 and 2 (construction)

- HD 308 S2 (core identification)

- IEC 60502-1 (European National Standards)

Frequently Asked Questions

What are the core colors?

- NYY & NAYY-J:

- 3 Core: Blue, Brown, Green/Yellow

- 4 Core: Brown, Black, Grey, Green/Yellow

- 5 Core: Brown, Black, Grey, Blue, Green/Yellow

- 7 Core and Above: Number Coded (Excluding NAYY)

- NYCY, NYCWY & NAYY-O:

- 2 Core: Brown, Blue

- 3 Core: Brown, Black, Grey

- 4 Core: Brown, Black, Grey, Blue

What do the abbreviations stand for?

- N: According to VDE Standard

- A: Aluminium Conductor

- Y: PVC Insulated

- C: Concentric conductors of copper wires and copper tape, helically wounded

- CW: Concentric conductor of copper wires in waveconal formation and copper tape, helically wounded

- J: Green/Yellow core exists

- O: No Green/Yellow core exists

What’s the difference between NYY and SWA?

NYY cables are more economical and flexible than SWA cables. While SWA provides increased mechanical protection, NYY is suitable where such protection is not required. Benefits of NYY over SWA include:

- Lower installation costs (reduced labor time)

- Greater flexibility and easier handling

- Lighter weight

- Lower overall cost (not affected by steel prices)

Why select NYCY or NYCWY?

These variants provide increased electrical and light mechanical protection. The concentric conductor can be used as:

- Neutral conductor

- Protective conductor

- Earthed conductor

- Screen for earth-connected protection against contact

NYCWY’s waveform construction allows for cable joints without cutting neutral conductors, as they can be formed into a bunch on each side of the phase conductors.

Are LSZH versions available?

Yes, LSZH (Low Smoke Zero Halogen) alternatives are available:

- NYY → N2XH

- NYCWY → N2XCH

- NAYY → NA2XH

These LSZH versions feature XLPE core insulation with a 90°C conductor temperature rating compared to 70°C for standard PVC versions.