When operating in the demanding environment of underground coal mines, reliable power delivery to mobile equipment isn’t just a matter of efficiency—it’s a critical safety requirement. The MY-0.38/0.66kV mining mobile equipment cable represents a specialized solution engineered specifically for these challenging conditions. This comprehensive guide explores the technical specifications, applications, and selection criteria for these essential mining cables that keep operations running safely and efficiently.

Understanding MY Cable Designation and Standards

The designation “MY” in mining cables carries specific meaning that indicates its application and construction:

- M: Stands for “Mining” or specifically “Coal Mine” application

- Y: Indicates “Mobile” or flexible cable construction

- 0.38/0.66kV: Specifies the voltage rating (0.38kV phase voltage, 0.66kV line voltage)

These cables are manufactured according to strict industry standards, primarily MT818.5-2009 in China, with equivalent international standards including IEC 60502 and various national mining safety regulations. All legitimate MY cables must carry appropriate mine safety certifications, most notably the MA (Mine Safety Approval) mark, without which they cannot legally be used in mining operations.

Technical Construction and Materials

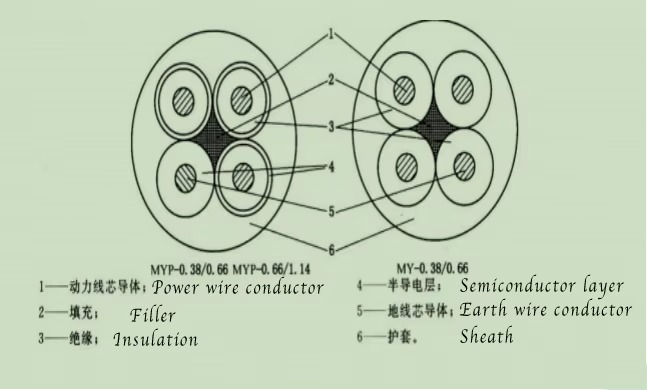

Core Structure

MY-0.38/0.66kV cables typically feature a multi-core construction designed for three-phase power distribution:

- Common configurations include 3+1 core arrangements (e.g., 3×25+1×16)

- The three primary conductors (typically 25mm²) carry the phase currents

- The fourth conductor (typically 16mm²) serves as the ground/neutral conductor

- Available in various conductor sizes ranging from 4mm² to 95mm² depending on current requirements

Material Composition

- Conductor: Flexible stranded copper, often tin-coated to prevent corrosion

- Insulation: Natural or synthetic rubber compounds with superior electrical properties

- Sheath/Jacket: Flame-retardant chloroprene (neoprene) or other specialized compounds

- Optional shielding: Some variants (designated MYP) include metallic or non-metallic shielding

Key Performance Parameters

- Operating temperature range: -20°C to +60°C (some premium variants operate from -45°C)

- Minimum bending radius: 6 times the cable diameter

- Insulation resistance: ≥50MΩ·km

- Test voltage: 2500V/5min without breakdown

- Flame retardancy: Certified to MT386 standards, passing alcohol burner tests

Critical Safety Features

Underground mining environments present unique hazards that demand specialized cable features:

- Flame Retardant Properties: MY cables are engineered to self-extinguish and prevent flame propagation in case of electrical faults.

- Oil and Chemical Resistance: Special rubber compounds resist degradation from exposure to oils, greases, and common mining chemicals.

- Mechanical Protection: Reinforced construction withstands crushing forces, impact damage, and abrasion common in mining operations.

- Ground Fault Protection: The dedicated ground conductor ensures proper equipment grounding to prevent electrical shock hazards.

- Smoke Emission Control: Low-smoke formulations minimize visibility reduction during emergency situations.

Applications in Mining Operations

MY-0.38/0.66kV cables serve as the lifeline for numerous mobile mining applications:

- Longwall and continuous mining machines: Primary power feed for cutting and extraction equipment

- Shuttle cars and load-haul-dump vehicles: Flexible power supply during material transport

- Mobile conveyors: Power distribution along conveyor systems that require repositioning

- Roof bolters and support installation equipment: Reliable power for critical safety equipment

- Ventilation systems: Power supply to temporary or repositionable ventilation equipment

- Pumping stations: Connection to dewatering equipment in wet mining sections

Selection Guidelines for Mining Engineers

Choosing the right MY cable requires careful consideration of several factors:

1. Current Capacity Requirements

Calculate the required conductor cross-section based on:

- Equipment power rating

- Duty cycle (continuous vs. intermittent operation)

- Ambient temperature derating factors

- Installation method (free air vs. confined space)

2. Mechanical Stress Considerations

- For equipment with frequent directional changes, select cables with enhanced flexibility

- High-abrasion areas require thicker sheathing or additional mechanical protection

- Consider tear resistance ratings for equipment operating in rocky environments

3. Certification Verification

Always verify:

- Valid MA certification mark

- Manufacturer’s compliance documentation

- Recent test certificates (typically valid for 1-2 years)

- Country-specific approvals for international operations

Leading Manufacturers and Quality Indicators

Reputable MY cable manufacturers typically demonstrate:

- ISO 9001 quality management certification

- Dedicated mining cable production lines

- In-house testing facilities that simulate underground conditions

- Comprehensive technical support and documentation

- Established track record in mining industry applications

Top manufacturers include specialized cable producers with mining expertise, particularly those with direct experience in coal mining applications. When evaluating suppliers, request sample test reports and installation references from similar mining operations.

Maintenance and Service Life Expectancy

Proper maintenance significantly extends MY cable service life:

- Regular inspection: Check for cuts, abrasions, swelling, or hardening of the sheath

- Proper handling: Avoid sharp bends during installation and operation

- Termination quality: Use proper connectors and sealing methods to prevent moisture ingress

- Storage conditions: Keep unused cable in cool, dry conditions away from direct sunlight

With proper care, quality MY-0.38/0.66kV cables typically deliver 3-5 years of reliable service in demanding mining environments, though actual lifespan varies based on specific operating conditions and handling practices.

Future Developments in Mining Cable Technology

The mining cable industry continues to evolve with several notable trends:

- Enhanced monitoring: Integration of conductor temperature monitoring systems

- Improved materials: New rubber compounds offering better cut-through resistance

- Sustainability focus: More environmentally friendly materials without compromising safety

- Digital integration: Cables with built-in communication channels for equipment monitoring

FAQ Section

Q: Can MY cables be used in non-mining applications?

A: While technically possible, MY cables are specifically certified and optimized for mining environments. Using them outside their certified applications may void warranties and safety certifications.

Q: What’s the difference between MY and MYP cables?

A: MYP cables include an additional shielding layer (the “P” denotes shielded) that provides electromagnetic interference protection and enhanced safety features for more demanding applications.

Q: How do I verify the authenticity of MY cable certifications?

A: Request the manufacturer’s certification documents and verify them through the issuing authority’s database. Legitimate certifications include unique identification numbers and validity dates.

Q: What’s the typical lead time for custom MY cable specifications?

A: Standard configurations are often available within 1-2 weeks, while custom specifications may require 3-6 weeks depending on complexity and manufacturer capacity.