What Does Cu/XLPE/SWA/PVC Actually Mean?

Understanding cable nomenclature is essential for making informed purchasing decisions. Each component in “Cu/XLPE/SWA/PVC” represents a specific layer or material:

- Cu: Copper conductor – provides excellent electrical conductivity and flexibility

- XLPE: Cross-Linked Polyethylene insulation – offers superior thermal and electrical properties

- SWA: Steel Wire Armor – galvanized steel wires providing mechanical protection and tensile strength

- PVC: Polyvinyl Chloride outer sheath – delivers environmental protection and flame retardancy

This construction creates a cable engineered specifically for harsh conditions where standard cables would fail prematurely.

Technical Specifications and Standards Compliance

Cu/XLPE/SWA/PVC cables typically comply with international standards including:

- BS5467: British Standard for armored cables

- IEC 60502: International standard for power cables

- ISO 9001: Quality management certification

- CCC, CE: Safety compliance certifications

Typical Electrical Characteristics:

| Conductor Size (mm²) | Voltage Rating | Max. Conductor Temp. | Bending Radius |

|---|---|---|---|

| 4-300 | 0.6/1kV | 90°C (normal operation) | 10x overall diameter |

| Insulation Thickness | Sheath Thickness | DC Resistance (20°C) | Current Carrying Capacity |

| 0.7-2.2mm | 1.8-3.3mm | Varies by size | According to IEC 60287 |

Applications: Where Cu/XLPE/SWA/PVC Cables Excel

These armored cables are specifically designed for demanding environments:

- Underground installations – direct burial without conduit

- Industrial facilities – factories, power plants, and manufacturing plants

- Outdoor distributions – exposed to weather elements and physical hazards

- Construction sites – temporary power with high mechanical stress

- Railway and transportation infrastructure – signaling and power systems

- Mining operations – hazardous environments requiring robust protection

- Marine and offshore installations – saltwater exposure and movement

The steel wire armor provides exceptional resistance against crushing forces, rodent damage, and tensile stress during installation and operation.

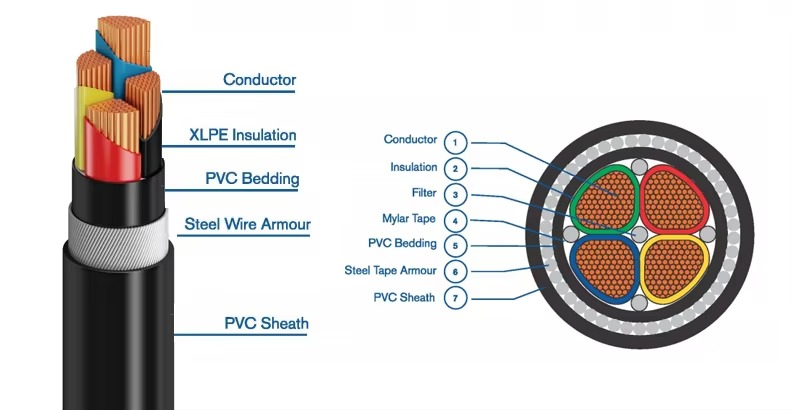

Cable Construction: Engineering for Performance

1. Conductor

Compact stranded copper conductors provide excellent flexibility while maintaining high conductivity. Available in single-core and multi-core configurations (2-core, 3-core, 4-core, etc.).

2. Insulation

XLPE (Cross-Linked Polyethylene) insulation offers:

- Higher temperature rating (90°C) compared to PVC

- Better electrical properties and dielectric strength

- Superior water-tree resistance

- Longer service life in demanding conditions

3. Inner Sheath

PVC bedding material separates the insulation from the armor, preventing damage during flexing and providing additional insulation protection.

4. Armor

Galvanized steel wire armor (SWA) provides:

- Mechanical protection against impact and crushing

- Rodent and vermin resistance

- Tensile strength for pulling during installation

- Additional earth continuity path

5. Outer Sheath

PVC outer sheath options include:

- Standard PVC: Good general-purpose protection

- FR-PVC (Flame Retardant): Enhanced fire performance

- LSZH (Low Smoke Zero Halogen): Reduced toxic emissions during fire

Selection Guide: Choosing the Right Cable for Your Project

Key Selection Factors:

- Current Requirements: Calculate load requirements considering derating factors for installation conditions

- Voltage Rating: Ensure compatibility with your system voltage (0.6/1kV for low voltage applications)

- Environmental Conditions: Consider temperature extremes, chemical exposure, UV radiation

- Installation Method: Direct burial, ducting, surface mounting, or suspended

- Regulatory Requirements: Local codes may mandate specific cable types for certain applications

- Future Expansion: Allow capacity for potential load increases

Common Sizes and Applications:

- Small sizes (4-16mm²): Control circuits, lighting circuits, small machinery

- Medium sizes (25-95mm²): Distribution circuits, medium machinery, sub-main feeders

- Large sizes (120-300mm²): Main feeders, high-power equipment, transformer connections

Installation Best Practices

Proper installation significantly impacts cable performance and lifespan:

- Bending Radius: Never bend below minimum specified radius (typically 10x overall diameter)

- Pulling Tension: Use proper pulling grips and lubricants; never exceed maximum tensile load

- Termination: Use appropriate glands and connectors designed for armored cables

- Earthing: Properly bond the steel armor at both ends for effective earth continuity

- Separation: Keep power cables separate from data/communication cables to prevent interference

- Support: Provide adequate support at recommended intervals to prevent stress on conductors

Maintenance and Troubleshooting

While Cu/XLPE/SWA/PVC cables require minimal maintenance, these practices extend service life:

- Regular Visual Inspections: Check for physical damage, especially at terminations

- Thermal Imaging: Identify hot spots indicating potential connection problems

- Insulation Resistance Testing: Periodic megger testing to verify insulation integrity

- Earth Continuity Verification: Ensure armor maintains proper earth connection

- Documentation: Maintain accurate records of cable routes, specifications, and test results

Cu/XLPE/SWA/PVC vs. Alternative Cable Types

| Feature | Cu/XLPE/SWA/PVC | Cu/XLPE/SWA/LSZH | Cu/PVC/SWA/PVC | Aluminum Conductor Cables |

|---|---|---|---|---|

| Mechanical Protection | Excellent | Excellent | Excellent | Excellent |

| Fire Performance | Good | Superior | Standard | Good |

| Current Capacity | High | High | Moderate | Lower (vs. same size Cu) |

| Cost | Moderate | Higher | Lower | Lower |

| Weight | Heavy | Heavy | Heavy | Lighter |

| Corrosion Resistance | Good | Good | Good | Better in some conditions |

Industry Applications Spotlight: Power Distribution in Mining

Mining operations present some of the harshest conditions for electrical infrastructure. A major Australian mining company recently upgraded their underground power distribution system using 3x95mm² Cu/XLPE/SWA/PVC cables. The results demonstrated:

- 40% reduction in cable failures compared to previous installations

- Elimination of costly production downtime due to cable damage

- Enhanced safety through reliable earthing via the steel armor

- Extended service life despite constant mechanical stress and moisture exposure

“The steel wire armor has proven essential in our high-risk environment,” notes the chief electrical engineer. “While the initial investment was higher than standard cables, the total cost of ownership is significantly lower due to reduced maintenance and replacement needs.”

Frequently Asked Questions

Q: What’s the difference between SWA (steel wire armor) and STA (steel tape armor)?

A: SWA uses interlocked galvanized steel wires providing superior tensile strength and crush resistance in all directions, making it ideal for vertical installations and direct burial. STA uses flat steel tapes primarily offering crush resistance but less tensile strength.

Q: Can Cu/XLPE/SWA/PVC cables be installed in water?

A: Yes, these cables are suitable for underwater installations when properly terminated. The XLPE insulation and steel armor provide excellent water resistance, though specific marine-grade variants may be recommended for permanent submersion.

Q: What’s the expected service life of these cables?

A: With proper installation and operating within specifications, Cu/XLPE/SWA/PVC cables typically provide 25-40 years of reliable service. XLPE insulation contributes significantly to this longevity compared to older insulation materials.

Q: Are there environmental concerns with PVC sheathing?

A: Standard PVC contains halogens that can produce toxic fumes when burned. For environmentally sensitive applications or confined spaces, consider LSZH (Low Smoke Zero Halogen) variants which offer similar protection with reduced toxicity during fire events.