What is BBTRZ Fire-Resistant Cable?

BBTRZ represents a breakthrough in fire safety technology—B is for mineral insulation, B for copper conductor, T for fire resistance, R for flexible, and Z for heavy-duty application. Unlike conventional fire-resistant cables that merely slow down fire propagation, BBTRZ cables deliver true circuit integrity under extreme conditions.

These advanced cables strictly comply with the British BS6387 standard, guaranteeing continuous operation for a minimum of three hours when exposed to fire temperatures reaching 950-1000°C. This critical timeframe provides emergency personnel with the window needed to evacuate occupants and protect valuable assets—making the difference between a controlled incident and a catastrophic disaster.

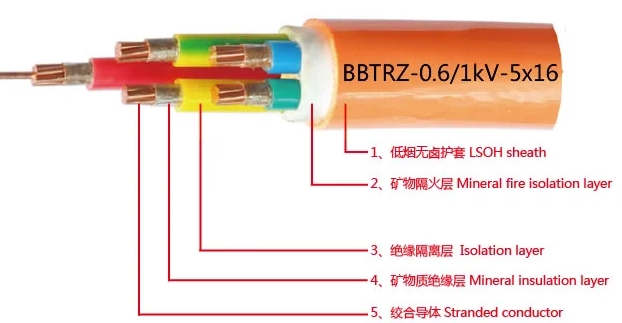

Advanced Construction: Engineering Safety Layer by Layer

1. High-Conductivity Copper Conductor

BBTRZ cables feature multi-stranded fine copper wires expertly twisted together. This design delivers exceptional flexibility while maintaining superior electrical performance. With bending radii as low as 6-10 times the cable diameter (depending on single or multi-core configuration), installation in tight spaces becomes significantly easier than with rigid alternatives.

2. Multi-Layer Mica Insulation

At the heart of BBTRZ technology lies multiple layers of premium mica tape insulation. This naturally occurring mineral withstands temperatures exceeding 1000°C while maintaining excellent dielectric properties. The overlapping layer technique ensures complete coverage with no weak points for thermal penetration.

3. Mineral Compound Filling

A proprietary blend of inorganic mineral compounds surrounds the insulated conductors, providing additional thermal protection and mechanical stability. This nanotechnology-enhanced filling material creates a thermal barrier that dramatically slows heat transfer to critical internal components.

4. Fire-Resistant Outer Sheath

The final protective layer consists of specialized low-smoke, zero-halogen (LSZH) materials that won’t contribute fuel to a fire. When exposed to extreme heat, this sheath chars rather than melts, maintaining circuit integrity while producing minimal smoke and absolutely no toxic halogen gases.

Unmatched Performance Characteristics

Uncompromising Fire Resistance

BBTRZ cables don’t just resist fire—they thrive in it. Certified to withstand the full BS6387 test regimen (including the demanding CWZ protocol), these cables maintain functionality through:

- 950°C direct flame exposure for 180 minutes

- Water spray exposure after fire exposure (W rating)

- Mechanical impact during fire conditions (Z rating)

This three-dimensional protection ensures power continuity even when buildings experience structural movement during fires.

Environmental Responsibility

In an era of increasing sustainability requirements, BBTRZ cables offer compelling eco-credentials:

- Zero toxic emissions when exposed to fire

- 100% recyclable materials at end-of-life

- No halogen content to create corrosive byproducts

- Estimated service life exceeding 100 years—drastically reducing replacement waste

Installation and Operational Advantages

- Superior flexibility compared to traditional mineral insulated cables

- Higher current-carrying capacity due to excellent heat dissipation

- Wider temperature tolerance (-25°C to +105°C operational range)

- Corrosion resistance suitable for harsh industrial environments

- EMI/RFI shielding properties beneficial for sensitive equipment

Critical Applications Where BBTRZ Cables Save Lives

Building Safety Systems

BBTRZ cables form the nervous system of modern fire safety infrastructure:

- Emergency lighting circuits

- Fire alarm and detection systems

- Firefighter elevator power supplies

- Smoke extraction and ventilation systems

- Stairwell pressurization systems

Transportation Infrastructure

The unique combination of flexibility and fire resistance makes BBTRZ ideal for:

- Underground railway power and signaling

- Airport terminal emergency systems

- Road and rail tunnel lighting and ventilation

- Marine vessel critical power circuits

- Air traffic control facility backup systems

Data and Critical Infrastructure

Where downtime equals disaster:

- Data center primary and backup power

- Hospital life-support system circuits

- Emergency communication networks

- Nuclear facility safety systems

- Banking and financial institution core operations

Industrial Applications

Harsh environments demand robust solutions:

- Petrochemical plant safety systems

- Steel mill process control

- Mining operation emergency circuits

- Offshore platform critical systems

- Wastewater treatment facility controls

BBTRZ vs. Traditional Fire-Resistant Solutions

| Feature | BBTRZ Cable | Traditional MICC (BTTZ) | Polymeric Fire-Resistant |

|---|---|---|---|

| Flexibility | Excellent (bend radius 6-10D) | Poor (rigid construction) | Good |

| Installation Ease | Simple, minimal special tools | Complex, requires specialists | Straightforward |

| Water Resistance | Excellent (W-rated) | Good with sealants | Varies, often poor |

| Toxic Emissions | None | None | Often significant |

| Impact Resistance | Excellent (Z-rated) | Poor (brittle) | Moderate |

| Termination Complexity | Standard industrial methods | Specialized techniques required | Standard methods |

| Cost Efficiency | Moderate initial cost, low lifetime cost | High initial cost | Low initial cost, high replacement cost |

Why Specifiers Choose BBTRZ for Critical Installations

Future-Proof Investment

While initial costs may be higher than conventional cables, BBTRZ delivers exceptional total cost of ownership:

- Elimination of costly fire barriers and protection systems

- Dramatically reduced insurance premiums in many jurisdictions

- No requirement for redundant circuit installations

- Maintenance-free operation for decades

- Protection against business interruption losses

Regulatory Compliance

BBTRZ cables help projects meet increasingly stringent building codes worldwide:

- BS 6387 (UK)

- IEC 60331 (International)

- NFPA 70 / NEC Article 700 (USA)

- AS/NZS 3000 (Australia/New Zealand)

- GB standards (China)

Implementation Best Practices

For optimal performance and safety compliance:

- Use dedicated BBTRZ-compatible termination kits

- Maintain separation from non-fire-rated circuits where possible

- Follow manufacturer bending radius specifications during installation

- Implement proper cable support systems to prevent stress

- Document circuit identification clearly for maintenance personnel

- Consider color-coding for critical vs. non-critical circuits

Frequently Asked Questions

What does the “Z” in BBTRZ stand for?

The “Z” originally designated “heavy-duty application” in Chinese cable nomenclature, representing the cable’s robust construction and ability to withstand severe conditions including mechanical impact during fire exposure.

Can BBTRZ cables be installed in existing buildings?

Yes, the superior flexibility of BBTRZ cables makes them ideal for retrofit projects. Their smaller bending radius compared to traditional mineral insulated cables allows installation in existing conduits and tight spaces where rigid alternatives would be impossible.

How do BBTRZ cables compare in cost to conventional options?

While BBTRZ cables typically cost 20-30% more than standard fire-resistant polymers, they often prove more economical than complete installation of traditional mineral insulated cables when labor, termination, and support hardware costs are factored in.

Do BBTRZ cables require special termination techniques?

BBTRZ cables use standard industrial termination methods similar to conventional cables, unlike rigid mineral insulated cables that require specialized termination kits and training. This significantly reduces installation time and cost.

Can BBTRZ cables be used outdoors?

Yes, with appropriate UV-resistant sheathing options, BBTRZ cables can be installed in outdoor applications, including direct burial and tray installations, providing the same fire protection benefits in exterior environments.