What is Bttw/Yttw/RTTZ Flexible Mineral Insulated Cable Supplier?

YTTW is a flexible copper-sheathed inorganic mineral insulated fire-resistant cable. It belongs to the family of mineral-insulated fire-resistant cables and represents a significant upgrade from traditional rigid mineral-insulated cables (such as BTTZ). YTTW effectively addresses the primary challenges associated with manufacturing and installation of conventional rigid cables (particularly poor flexibility and length limitations), while maintaining superior fire-resistant performance.

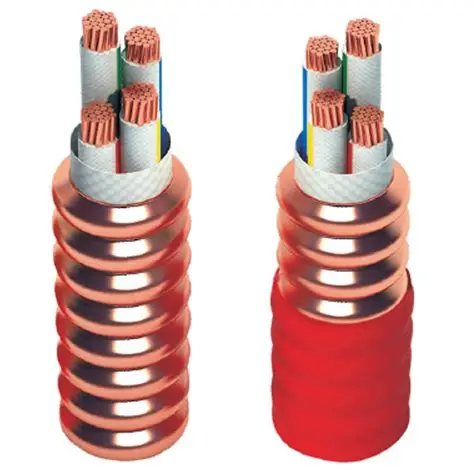

YTTW Cable Structure

The name YTTW represents the following characteristics:

- Y: Typically represents the “series code” or emphasizes its “flexible” characteristics (compared to traditional rigid cables).

- T (first): Indicates copper conductor.

- T (second): Indicates copper sheath.

- W: Indicates inorganic mineral insulating layer.

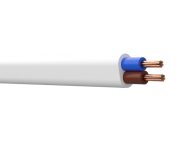

The core structure of YTTW cable, from inner to outer layer, consists of:

Conductor

The conductor is made of multi-strand fine copper wires twisted into a circular compact conductor. This structural design provides the cable with excellent flexibility, making it easy to bend and install in various applications.

Insulation Layer

This is the key distinguishing feature of YTTW compared to traditional BTTZ cables. It employs high-temperature resistant (typically >1000°C) inorganic synthetic mineral materials (such as modified mica, ceramic silicates, etc.) combined with reinforcing materials to form fire-resistant tapes. These tapes are tightly overlapped and wound around the conductor to create a stable and reliable insulation layer.

Filling/Isolation Layer (Optional)

Depending on the cable core configuration, optional components may include:

- Inorganic fillers (such as fire-resistant rope) to ensure circularity

- A non-hygroscopic isolation tape (such as alkali-free glass tape) for additional protection

Sheath

A continuously longitudinally wrapped and welded copper tape sheath. This is the signature structural feature of YTTW. Specialized equipment wraps copper tape longitudinally around the cable core and welds the seam securely, forming a continuous, sealed, and robust tubular metal protective layer. This copper sheath serves as the core component providing fire barrier protection, mechanical strength, and grounding path.

Outer Sheath (Optional)

Depending on specific application requirements and environmental conditions, an additional plastic outer sheath may be applied over the copper sheath, such as:

- Halogen-free low-smoke flame-retardant polyolefin (WDZ)

- High-density polyethylene (HDPE)

This optional outer sheath provides enhanced protection against moisture, corrosion, and ultraviolet radiation.