What Is 0.6/1 kV RV-K Power Cable?

The 0.6/1 kV RV-K power cable is a flexible, single-core or multi-core cable designed for power transmission and distribution in fixed installations. The designation “0.6/1 kV” refers to its voltage rating – 0.6 kV between conductor and earth, and 1 kV between conductors. This makes it suitable for low-voltage applications where reliability and durability are paramount.

The “RV-K” classification indicates specific construction characteristics:

- R – Rubber/flexible insulation

- V – PVC sheath

- K – Flexible conductor class

These cables feature electrolytic copper conductors with cross-linked polyethylene (XLPE) insulation and a PVC outer sheath. This combination provides excellent electrical properties, mechanical strength, and resistance to environmental factors. RV-K cables are designed for fixed installations both indoors and outdoors, including industrial plants, commercial buildings, power stations, and distribution networks.

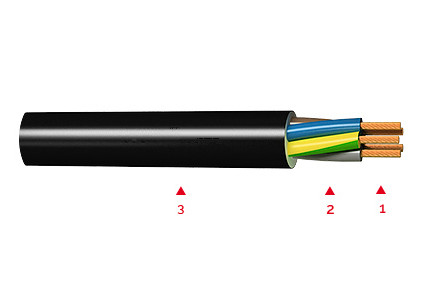

Construction

1. Conductor:Flexible electrolytic copper conductor (Class V) according to BS EN 60228:2005 (previously BS6360), UNE 60228 and IEC 60228

2. Insulation: Cross-linked polyethylene (XLPE), type DIX-3, according to UNE 21123 and HD 603S1

Number of Cable Cores: one core (single core), two cores (double core), three cores

Core Structure: concentric stranding of cores

3. Sheath:PVC sheath type DMV-18, according to HD 603S1.

Key Parameters and Specifications

Understanding the technical specifications of 0.6/1 kV RV-K cables is crucial for proper selection and installation:

| Parameter | Specification Details |

|---|---|

| Voltage Rating | 0.6/1 kV (600/1000V) |

| Conductor | Class 5 flexible annealed copper according to IEC 60228 |

| Insulation Material | Cross-linked polyethylene (XLPE) |

| Outer Sheath | Polyvinyl chloride (PVC) |

| Core Configuration | Available in 1, 2, 3, 4, or 5 cores |

| Conductor Size Range | Typically 1.5mm² to 300mm² |

| Operating Temperature | -15°C to +90°C (short circuit up to 250°C) |

| Minimum Bending Radius | 6× overall diameter for fixed installation |

| Standards Compliance | IEC 60502-1, VDE 0250, BS 6004, and other international standards |

| Flame Retardant | IEC 60332-1-2 compliant (flame retardant) |

| UV Resistance | Suitable for outdoor installation with UV-resistant sheath |

Color Coding:

- Single-core: Typically black, red, blue, yellow, or green/yellow for protective conductors

- Multi-core: Standard color coding for phase identification

How RV-K Cables Differ From Other Power Cables

Understanding the unique characteristics of 0.6/1 kV RV-K cables compared to alternatives helps in making the right selection:

RV-K vs. Standard PVC Insulated Cables (VV, VVG)

- Temperature Rating: RV-K cables with XLPE insulation withstand higher temperatures (90°C) compared to PVC-insulated cables (70°C), allowing for greater current-carrying capacity

- Durability: XLPE insulation provides better resistance to environmental stress and aging

- Flexibility: RV-K cables typically offer better flexibility due to class 5 conductors

RV-K vs. Rubber Insulated Cables (H07RN-F)

- Chemical Resistance: RV-K PVC sheathing offers better resistance to oils and chemicals than standard rubber cables

- Cost: RV-K cables are generally more cost-effective than rubber-insulated counterparts

- Temperature Range: Rubber cables typically have a wider operating temperature range

RV-K vs. Armored Cables (SWA)

- Installation Ease: Non-armored RV-K cables are lighter and easier to install in accessible locations

- Flexibility: RV-K cables offer better flexibility for routing through tight spaces

- Protection Level: Armored cables provide superior mechanical protection where required

- Application: RV-K is ideal for protected installations, while armored cables excel in direct burial or exposed locations

Applications and Use Cases

The versatility of 0.6/1 kV RV-K power cables makes them suitable for numerous applications:

- Industrial Facilities: Power distribution in factories, manufacturing plants, and processing facilities

- Commercial Buildings: Lighting circuits, HVAC systems, and power distribution in offices and retail spaces

- Renewable Energy: Solar and wind power installations, particularly for internal connections

- Infrastructure Projects: Transportation systems, tunnels, and public utilities

- Residential Complexes: Main power distribution in apartment buildings and housing developments

- Temporary Installations: Construction sites and event venues requiring reliable power distribution

Installation and Maintenance Guidelines

Proper installation and maintenance ensure optimal performance and longevity of 0.6/1 kV RV-K cables:

Installation Best Practices:

- Ensure ambient temperature remains above 0°C during installation

- Respect minimum bending radius requirements (typically 6× cable diameter)

- Use appropriate cable glands and terminations rated for the cable type

- Maintain separation from communication cables to prevent interference

- Follow local electrical codes for support spacing and routing

Maintenance Recommendations:

- Conduct periodic visual inspections for physical damage or degradation

- Perform thermal imaging to identify potential hot spots in connections

- Test insulation resistance annually or as recommended by local regulations

- Replace damaged sections promptly rather than attempting repairs

Frequently Asked Questions

Q1: What does “0.6/1 kV” mean in cable designation?

The “0.6/1 kV” rating indicates the voltage levels the cable is designed to handle safely. The first number (0.6 kV) represents the maximum voltage between any conductor and earth/ground. The second number (1 kV) represents the maximum voltage between conductors. This rating makes these cables suitable for standard low-voltage power distribution systems.

Q2: Can RV-K cables be installed underground?

Yes, 0.6/1 kV RV-K cables can be installed underground, but they should be protected with conduit or ducting. For direct burial applications without protection, cables with additional mechanical protection (like armored variants) are recommended.

Q3: What’s the expected service life of RV-K cables?

When properly installed and maintained under recommended operating conditions, 0.6/1 kV RV-K cables typically have a service life exceeding 30 years. Factors such as operating temperature, exposure to sunlight, chemical exposure, and mechanical stress can affect longevity.

Q4: Are RV-K cables fire resistant?

Standard RV-K cables are flame retardant (complying with IEC 60332-1-2), meaning they will not propagate fire. However, for installations requiring enhanced fire safety, specialized variants with low-smoke zero-halogen (LSZH) sheathing are available.

Q5: How do I determine the correct cable size for my application?

Cable sizing depends on:

- Load current requirements

- Allowable voltage drop

- Short circuit withstand capability

- Installation method and ambient temperature

- Grouping factors if multiple cables are installed together Always consult relevant electrical codes and consider having calculations performed by a qualified electrical engineer.

Q6: Can RV-K cables be used in wet locations?

Yes, 0.6/1 kV RV-K cables are suitable for damp and wet locations. The XLPE insulation and PVC sheath provide excellent moisture resistance. However, ensure proper sealing of terminations to prevent water ingress at connection points.