What Is YJV32 Cable?

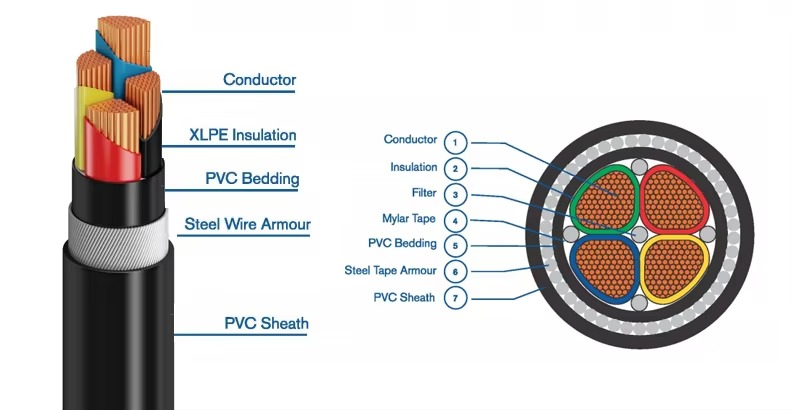

YJV32 represents one of the most robust armored power cable solutions in modern electrical infrastructure. This specialized cable features a copper conductor with cross-linked polyethylene (XLPE) insulation, fine steel wire armor, and polyvinyl chloride (PVC) outer sheathing. The “YJ” in its designation refers to cross-linked polyethylene insulation, “V” indicates the PVC sheath, while “32” specifically identifies its fine steel wire armor construction.

Engineered for demanding environments, YJV32 cables deliver exceptional mechanical protection alongside reliable electrical performance. These cables typically serve in applications requiring significant tensile strength, including vertical installations, mining operations, and areas with substantial elevation differences where standard cables would fail under mechanical stress.

The complete technical designation for this cable is “Copper Conductor Cross-Linked Polyethylene Insulated Fine Steel Wire Armored PVC Sheathed Power Cable,” reflecting its comprehensive protective design philosophy.

Technical Parameters of YJV32 Cable

Voltage Ratings & Configurations

YJV32 cables support various voltage classes to accommodate diverse power distribution needs:

- Low voltage: 0.6/1kV

- Medium voltage: 1.8/3kV, 3.6/6kV, 6/10kV, 8.7/15kV, 12/20kV

- High voltage applications up to 500kV (specialized variants)

Conductor Specifications

Available in multiple core configurations with varying cross-sectional areas:

- Single-core: 1×10mm², 1×16mm², 1×25mm², up to 1×630mm²

- Three-core: 3×1.5mm², 3×2.5mm², 3×4mm², and larger configurations

- Four-core and five-core variants for complex distribution systems

Performance Characteristics

- Operating temperature range: -20°C to +90°C (short circuit)

- Maximum conductor temperature: 90°C under normal operation

- Bending radius: Minimum 15 times the cable diameter for single-core, 10 times for multi-core

- Installation temperature: Must be above 0°C

- Armor protection: Galvanized fine steel wires providing exceptional tensile strength

- Standards compliance: GB/T12706.2/3, IEC 60502, and other international standards

Mechanical Properties

- Tensile strength: Significantly higher than non-armored or tape-armored variants

- Crush resistance: Moderate to high (secondary to tensile strength)

- Flexibility: Optimized for dynamic installations with vibration resistance

- Water resistance: Excellent sealing properties prevent moisture penetration

- Chemical resistance: Withstands exposure to oils, acids, and alkalis common in industrial environments

YJV32 vs. Other Power Cables: Key Differences

YJV32 vs. YJV22: Critical Distinctions

The comparison between YJV32 and YJV22 represents one of the most important selection decisions for power cable installations. These seemingly similar cables serve fundamentally different mechanical protection purposes:

| Feature | YJV32 Cable | YJV22 Cable |

|---|---|---|

| Armor Type | Fine steel wire armor | Steel tape armor |

| Primary Protection | Superior tensile strength | Superior pressure resistance |

| Installation Orientation | Vertical runs, high elevation differences | Horizontal burial, direct burial |

| Typical Applications | Mines, vertical shafts, suspension bridges | Underground ducts, direct burial in stable soil |

| Flexibility | Moderate (rigid structure) | Higher (tape allows more bending) |

| Weight | Heavier due to wire armor | Lighter than wire-armored equivalent |

YJV32 vs. Non-Armored YJV Cables

Non-armored YJV cables lack the mechanical protection that makes YJV32 suitable for harsh environments. While standard YJV cables work well for indoor installations within protective conduits, they cannot withstand direct burial, rodent attacks, or significant mechanical stresses that YJV32 handles routinely.

YJV32 vs. YJV42 Cables

YJV42 cables feature coarse steel wire armor rather than the fine steel wire used in YJV32. This construction difference makes YJV42 more suitable for underwater installations and applications requiring extreme mechanical protection, while YJV32 offers better flexibility for most industrial vertical applications.

Common Questions About YJV32 Cable

What environments are YJV32 cables best suited for?

YJV32 cables excel in environments requiring high tensile strength: vertical shaft installations in high-rise buildings, mining operations, suspension bridge power distribution, offshore platforms, and any application with significant elevation changes. Their sealed construction also makes them suitable for areas with chemical exposure or high humidity.

Can YJV32 cables be directly buried underground?

Yes, YJV32 cables are specifically designed for direct burial applications. The fine steel wire armor provides protection against soil pressure, rodent damage, and mechanical stresses encountered during installation and throughout the cable’s operational life. However, proper bedding material and installation techniques remain essential.

What’s the maximum installation length for YJV32 cable?

The maximum installation length depends on multiple factors including voltage class, conductor size, and installation method. For vertical installations, tension calculations become critical. Generally, single-pull installations can reach 500-1000 meters for medium voltage applications, but segmented installation with intermediate supports may be necessary for extreme heights or distances.

How does temperature affect YJV32 cable performance?

YJV32 cables maintain stable performance across a wide temperature range. The XLPE insulation provides excellent thermal stability up to 90°C during normal operation. However, installation should never occur below 0°C as the cable materials can become brittle. For cold climate installations, special warming procedures may be required before deployment.

What’s the expected service life of YJV32 cable?

When properly installed and maintained within specifications, YJV32 cables typically deliver 30+ years of service life. This longevity stems from the excellent water-blocking properties of the armor system and the inherent stability of cross-linked polyethylene insulation, which resists degradation far better than standard PVC insulation.

Expert Buying Guide: Selecting the Right YJV32 Cable

Assess Your Application Requirements

Before purchasing YJV32 cable, conduct a thorough analysis of your installation environment:

- Calculate the maximum tensile forces the cable will experience

- Determine voltage class and current requirements

- Evaluate environmental factors (chemicals, temperature extremes, water exposure)

- Consider installation method (vertical, horizontal, suspended)

Quality Indicators to Verify

When comparing YJV32 cables from different manufacturers:

- Conductor purity: Look for oxygen-free copper conductors meeting IEC 60228 Class 2 standards

- Armor construction: Verify proper galvanization of steel wires and appropriate lay length

- Insulation quality: Request XLPE material certifications ensuring proper cross-linking percentage

- Sheath compound: Confirm UV-resistant PVC formulation for outdoor applications

- Certifications: Require compliance documentation for GB/T12706.2/3, IEC, UL, or other relevant standards

Cost Considerations vs. Value

While YJV32 cables command premium pricing compared to non-armored alternatives, consider the total cost of ownership:

- Installation labor savings from direct burial capability

- Reduced maintenance requirements

- Extended service life compared to replacement alternatives

- Lower risk of costly downtime from cable failure