What is YJV22 Cable?

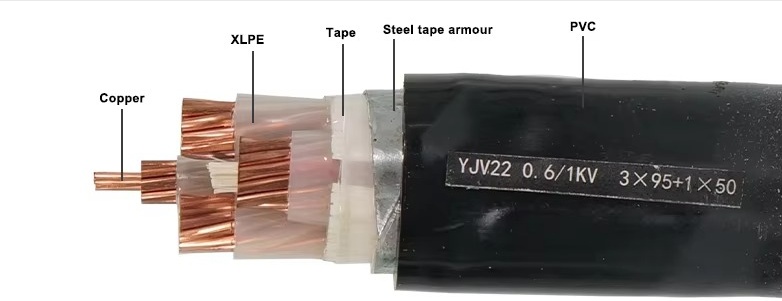

YJV22 cable is a copper conductor, cross-linked polyethylene (XLPE) insulated, PVC sheathed, steel tape armored power cable designed for demanding electrical applications. The name itself reveals its construction:

- YJ: Cross-linked polyethylene (XLPE) insulation

- V: Polyvinyl chloride (PVC) inner sheath

- 22: Double steel tape armor with PVC outer sheath

Manufactured according to international standards including GB12706 and IEC specifications, YJV22 cables are engineered for power distribution systems operating at 0.6/1kV voltage ratings. Their robust construction makes them particularly suitable for direct burial applications where mechanical protection is essential.

The steel tape armor layer provides exceptional resistance against physical damage, rodent attacks, and environmental stressors, making YJV22 the preferred choice for industrial facilities, utility infrastructure, and construction projects where cable protection is paramount.

Key Technical Parameters of YJV22 Cable

Electrical Characteristics

- Rated Voltage: 0.6/1kV (U₀/U)

- Conductor Material: Copper (if aluminum were used, the designation would include “L” as in YJLV22)

- Maximum Operating Temperature: 90°C under normal conditions

- Short Circuit Temperature: Up to 250°C (maximum duration of 5 seconds)

- System Frequency: 50Hz

Mechanical Properties

- Minimum Bending Radius:

- Single-core cables: 15× outer diameter (15D)

- Multi-core cables: 12× outer diameter (12D)

- Installation Temperature: Not below 0°C

- Armor Type: Double steel tape (provides superior crush resistance)

Available Configurations

- Core Configurations: 1, 2, 3, 4, 5, 3+1, 3+2, 4+1 cores

- Conductor Cross-sections: 2.5mm² to 400mm² (standard sizes include 2.5, 4, 6, 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240, 300, 400mm²)

- Special Variants:

- Flame retardant (ZR-YJV22)

- Fire resistant (NH-YJV22)

- Low smoke zero halogen (LSZH) versions

- Combined properties (flame retardant + fire resistant + LSZH)

Current Carrying Capacity

The current carrying capacity varies based on installation method, ambient temperature, and grouping. For example, a 3-core 95mm² YJV22 cable installed in air at 40°C typically carries approximately 250A, while the same cable buried in soil at 25°C can carry around 290A.

How YJV22 Differs from Other Cable Types

YJV22 vs. Standard YJV Cable

The critical difference is the steel tape armor. Standard YJV cables lack this protective layer, making them unsuitable for direct burial or environments where mechanical protection is required. YJV22’s armor provides:

- Superior crush resistance

- Protection against rodent damage

- Enhanced durability in rocky terrain

- Additional grounding capability through the armor layer

YJV22 vs. Other Armored Cables

Cable armor comes in several varieties, each serving distinct applications:

- YJV22 (Steel Tape Armor): Ideal for direct burial where protection against crushing forces is needed. Common in general industrial applications and utility distribution.

- YJV32/YJV33 (Fine Steel Wire Armor): Better suited for applications requiring greater tensile strength and flexibility, such as vertical installations in mines or underwater applications.

- YJV42/YJV43 (Coarse Steel Wire Armor): Used in extremely demanding environments requiring maximum mechanical protection and tensile strength.

YJV22 vs. Aluminum Conductor Variants

While YJV22 features copper conductors, the YJLV22 variant uses aluminum conductors. Copper versions offer:

- Better conductivity (approximately 60% higher than aluminum)

- Superior corrosion resistance

- Higher tensile strength

- Better termination reliability

- Higher cost per meter but sometimes lower total installation cost due to smaller cross-sections needed

Frequently Asked Questions About YJV22 Cable

What does each part of “YJV22” represent?

The designation follows a standardized coding system:

- YJ: Cross-linked polyethylene (XLPE) insulation

- V: PVC inner sheath or bedding

- First “2”: Steel tape armor

- Second “2”: PVC outer sheath If the conductor were aluminum instead of copper, the designation would include “L” (as in YJLV22).

Can YJV22 cable be installed without conduit when buried directly?

Yes, one of the primary advantages of YJV22 is its suitability for direct burial without additional conduit. The steel tape armor provides sufficient mechanical protection against soil pressure, rocks, and minor ground movement. However, local electrical codes should always be consulted, as some jurisdictions may have specific requirements for burial depth or additional protection in certain applications.

What’s the expected service life of YJV22 cable?

With proper installation and operation within rated parameters, YJV22 cables typically provide 30+ years of reliable service. The cross-linked polyethylene insulation is particularly resistant to thermal degradation compared to standard PVC insulation, contributing to the extended service life.

How do I calculate the required cross-section for my application?

Selecting the appropriate cross-section requires consideration of:

- Load current requirements

- Acceptable voltage drop

- Short circuit withstand capability

- Installation method (direct burial, in conduit, tray, etc.)

- Ambient temperature

- Grouping effects (derating for multiple cables) A qualified electrical engineer should perform these calculations following local regulations and international standards such as IEC 60364.

Can the steel armor be used as an earth conductor?

While the steel tape armor does provide a conductive path and can be grounded at termination points for safety, it should not be relied upon as the sole protective earth conductor in most applications. The armor’s electrical resistance is higher than copper conductors, and its primary purpose is mechanical protection. Most electrical codes require a dedicated earth conductor within the cable or installed alongside it.

How do I properly terminate YJV22 cable?

Proper termination of YJV22 cable requires:

- Careful removal of the outer PVC sheath without damaging the armor

- Proper termination of the armor to grounding points using appropriate armor clamps

- Removal of inner sheath to expose conductors

- Termination of conductors with suitable lugs or connectors

- Sealing against moisture ingress, especially for outdoor applications

- Following manufacturer guidelines for minimum bending radius during installation