What Is XLPE SWA Cable?

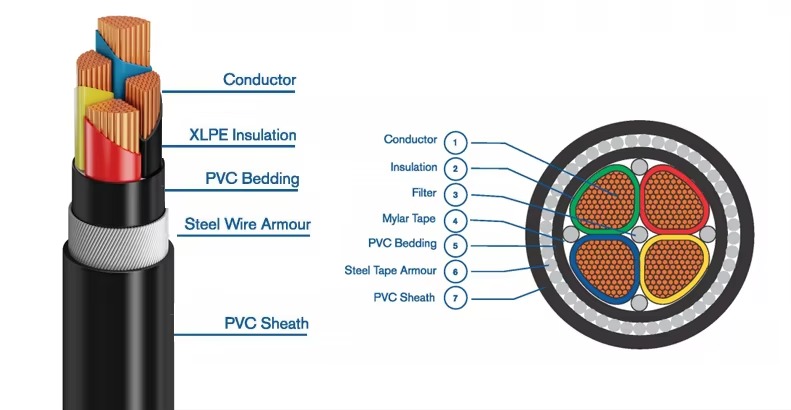

XLPE SWA cable (Cross-Linked Polyethylene Steel Wire Armored cable) is a heavy-duty power cable designed for demanding environments. Its construction features:

- XLPE Insulation: A thermoset polymer created by cross-linking polyethylene molecules, offering superior thermal stability (up to 90°C), moisture resistance, and longevity compared to PVC alternatives.

- Steel Wire Armor (SWA): A layer of galvanized steel wires wrapped around the insulation, providing crush resistance, rodent protection, and mechanical strength.

- Outer Sheath: Typically PVC or LSZH (Low Smoke Zero Halogen) material, shielding against UV exposure, chemicals, and abrasion.

This robust design makes XLPE SWA cables ideal for direct burial, underground ducts, and areas prone to physical stress.

5 Key Benefits of XLPE SWA Cables

- Unmatched Durability

The steel wire armor withstands extreme pressure, impact, and digging hazards, reducing failure risks in construction zones or industrial sites. - Enhanced Safety

XLPE insulation resists fire propagation, short circuits, and electrical faults. Its non-toxic properties (when LSZH-sheathed) minimize smoke and toxic gas emissions during fires. - Long Service Life

Resistant to water ingress, chemicals, and temperature fluctuations (-20°C to 90°C), XLPE SWA cables often exceed 30+ years of service with minimal degradation. - Cost Efficiency

Though pricier upfront than unarmored cables, their longevity and reduced maintenance needs lower total lifecycle costs. - Versatile Voltage Ratings

Available in low-voltage (600/1000V) to medium-voltage (up to 33kV) configurations, they suit diverse applications from residential grids to wind farms.

Where Are XLPE SWA Cables Used?

These cables excel in environments where reliability trumps convenience:

- Underground Power Networks: Direct burial in streets, parks, and campuses without conduit.

- Industrial Facilities: Factories, mines, and refineries exposed to oils, vibrations, and heavy machinery.

- Renewable Energy Projects: Solar/wind farms requiring cables resilient to weather and soil stress.

- Rail and Tunnel Systems: Critical infrastructure needing fire-resistant, high-integrity cabling.

- Marine and Coastal Installations: Corrosion-resistant variants protect against saltwater exposure.

XLPE SWA vs. Alternatives: Why Choose Armored?

| Cable Type | Best For | Limitations |

|---|---|---|

| XLPE SWA | Harsh, high-risk areas | Higher initial cost, heavier weight |

| PVC Unarmored | Indoor, low-stress zones | Vulnerable to damage, water ingress |

| Aluminum Armored | Lightweight outdoor use | Less crush-resistant than steel |

Key Insight: While unarmored cables save costs in controlled environments, XLPE SWA’s protection against mechanical and environmental threats makes it the smarter choice for critical infrastructure.

Installation Best Practices

Maximize performance with these expert tips:

- Bend Radius: Never exceed 12x the cable diameter during installation to avoid damaging conductors.

- Trench Preparation: Use sand bedding in burial sites to prevent sharp rocks from puncturing the armor.

- Termination: Seal ends immediately after cutting to block moisture ingress. Use certified glands for armor grounding.

- Testing: Perform insulation resistance (IR) and continuity tests pre/post-installation per IEC 60502 standards.

Maintenance Tips for Longevity

- Inspect Regularly: Check for sheath damage, corrosion, or ground movement in buried sections.

- Monitor Load Capacity: Avoid sustained overloading to prevent thermal degradation of XLPE.

- Update Aging Systems: Replace cables showing cracks, discoloration, or reduced insulation resistance.

FAQs About XLPE SWA Cables

Q1: Can XLPE SWA cables be submerged underwater?

A: Yes—special waterproof variants with longitudinal water-blocking tapes are rated for wet conditions, including river crossings. Verify IP68 ratings for submersion projects.

Q2: Is XLPE better than PVC insulation?

A: Absolutely. XLPE handles higher temperatures (90°C vs. 70°C for PVC), resists cracking in cold weather, and has a longer lifespan. It’s the default choice for critical infrastructure.

Q3: What standards apply to XLPE SWA cables?

A: Reputable manufacturers comply with IEC 60502 (international), BS 5467 (UK), and ICEA S-94-649 (North America). Always request test certifications.

Q4: How do I ground the steel armor?

A: Bond the armor to an earth terminal at both ends using exothermic welding or mechanical clamps to prevent induced voltages and ensure safety.

Company Information

·Tel/WhatsApp/WeChat: +86 135 8571 9693

·Email: henry@cncablemanufacture.com