What Is STA Armored Power Cable?

STA armored power cable, also known as Steel Tape Armored cable, represents one of the most robust solutions in electrical power distribution systems. This specialized cable features a protective layer of steel tape armor beneath its outer sheath, providing exceptional mechanical protection against impacts, crushing forces, and rodent damage.

Engineered for demanding environments, STA armored cables serve as the backbone of electrical infrastructure in industrial facilities, commercial buildings, and challenging outdoor installations where standard cables would quickly fail. The distinctive armor layer transforms vulnerable conductors into resilient power delivery systems capable of withstanding the harshest conditions.

Construction and Design Features

Core Components of STA Armored Cables

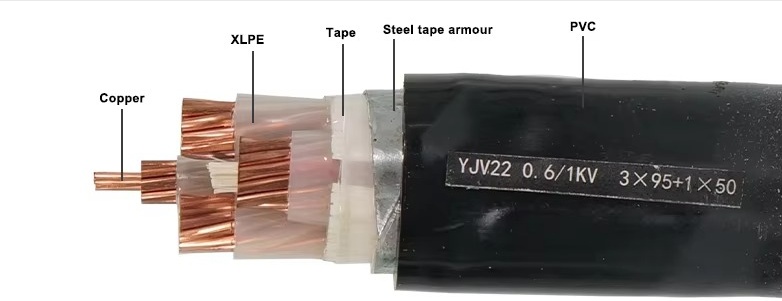

Understanding the layered construction of STA armored power cables reveals why they deliver superior performance:

- Conductor: Typically made of high-conductivity copper or aluminum, available in various cross-sections from 1.5mm² to 630mm²

- Insulation: Cross-linked polyethylene (XLPE) or PVC materials providing excellent electrical properties and thermal resistance

- Bedding Layer: A protective inner sheath that cushions the insulation before armor application

- Steel Tape Armor: Two layers of galvanized steel tape applied helically in opposing directions, forming the defining protective feature

- Outer Sheath: Robust PVC or LSZH (Low Smoke Zero Halogen) material providing environmental protection and color coding

This multi-layered design creates a comprehensive defense system against mechanical, chemical, and environmental threats while maintaining flexibility for practical installation.

Technical Specifications and Industry Standards

STA armored power cables adhere to stringent international standards ensuring quality and performance consistency:

- IEC 60502: International standard for power cables rated up to 30kV

- BS 5467: British standard for armored cables with PVC or XLPE insulation

- ICEA S-94-649: American standard for power cables

- Voltage Ratings: Commonly available in 0.6/1kV, 3.6/6kV, 6.35/11kV, and 8.7/15kV configurations

- Temperature Range: Typically -20°C to +90°C for XLPE insulated variants during operation

Manufacturers rigorously test these cables for tensile strength, bending radius limitations, fire resistance, and electrical performance under load to guarantee reliability throughout their service life.

Key Applications of STA Armored Power Cables

Where These Cables Excel

STA armored power cables dominate in applications requiring maximum protection and durability:

- Underground Installations: Direct burial without conduit in industrial complexes, campuses, and utility infrastructure

- Industrial Environments: Manufacturing plants, processing facilities, and heavy machinery applications

- Construction Sites: Temporary power distribution where cables face constant movement and potential damage

- Mining Operations: Both surface and underground mining electrical systems

- Marine and Offshore: Shipboard wiring and offshore platform power distribution

- Railway Systems: Signaling, lighting, and power distribution along rail corridors

- Renewable Energy: Solar farm interconnections and wind turbine power collection systems

The versatility of STA armored cables makes them indispensable across sectors where electrical failure is not an option.

Advantages Over Non-Armored Alternatives

Why Choose Armored Protection?

Selecting STA armored power cables delivers significant operational advantages:

- Superior Mechanical Protection: Resists crushing, impact damage, and rodent penetration that would compromise standard cables

- Enhanced Longevity: Properly installed armored cables often exceed 30+ years of service life

- Elimination of Conduit: Reduces material costs and installation time by removing the need for protective conduit in many applications

- Grounding Capability: The steel armor can serve as an equipment grounding conductor in certain configurations, reducing material requirements

- Fire Resistance: Many variants feature flame-retardant compounds that limit fire spread

- Environmental Resistance: Protection against moisture ingress, chemical exposure, and UV radiation

- Reduced Maintenance Costs: Fewer failures and repairs over the cable’s operational lifetime

While initial investment may be higher than non-armored alternatives, the total cost of ownership favors STA armored cables in demanding applications.

Installation Best Practices

Maximizing Performance and Safety

Proper installation ensures STA armored power cables deliver their full potential:

- Bending Radius: Maintain minimum bending radius (typically 12-15 times the cable diameter) during installation to prevent armor damage

- Termination Techniques: Use specialized gland fittings designed specifically for armored cables to maintain protection integrity

- Pulling Tension: Monitor pulling tension with dynamometers to avoid conductor stretching or insulation damage

- Grounding Protocol: Properly ground the steel armor at both ends unless specific installation requirements dictate otherwise

- Support Spacing: Secure cables at appropriate intervals (typically 0.8-1.2m horizontally, 0.6-1m vertically) using non-corrosive fixings

- Environmental Considerations: Select appropriate outer sheath materials (LSZH for confined spaces, UV-resistant for outdoor exposure)

Professional installation by certified electricians familiar with armored cable systems is strongly recommended to ensure compliance with local electrical codes and optimal performance.

Selection Guidelines for Your Project

Making the Right Choice

Choosing the appropriate STA armored power cable requires careful consideration:

- Determine Voltage Requirements: Match cable rating to system voltage with appropriate safety margins

- Calculate Current Capacity: Consider ambient temperature, grouping factors, and installation method for accurate derating

- Assess Environmental Challenges: Identify exposure to chemicals, moisture, temperature extremes, or physical hazards

- Verify Compliance Needs: Confirm alignment with local electrical codes and industry-specific regulations

- Evaluate Future Expansion: Allow capacity for potential load increases to avoid premature replacement

- Consider Life Cycle Costs: Factor in installation expenses, expected service life, and maintenance requirements

Consulting with cable manufacturers or electrical engineers for complex installations ensures optimal selection based on your specific application requirements.

Maintenance and Inspection Protocols

Ensuring Continued Reliability

Even robust STA armored cables benefit from systematic maintenance:

- Visual Inspections: Check for visible damage to outer sheaths, particularly at terminations and points of stress

- Thermal Imaging: Periodically scan connections and cable runs for abnormal heating patterns

- Insulation Resistance Testing: Perform megger testing to detect developing insulation issues

- Ground Continuity Verification: Confirm proper grounding of the armor throughout the installation

- Documentation: Maintain detailed records of installation dates, specifications, and maintenance activities

Early detection of potential issues extends service life and prevents unexpected failures in critical power systems.