What Is VV32 Armoured Power Cable?

VV32 armoured power cable is a multi-core electrical cable featuring PVC insulation and sheathing with steel wire armour designed for mechanical protection. The “VV” designation indicates PVC insulation and PVC sheathing, while the “32” refers to the specific type of armouring – in this case, fine steel wires applied helically over the bedding.

Unlike standard cables, VV32 variants are engineered to withstand extreme physical stress, moisture exposure, and harsh environmental conditions, making them ideal for demanding industrial applications where cable integrity is non-negotiable.

Technical Specifications and Construction

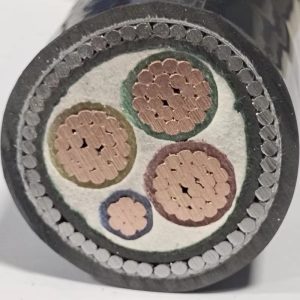

Core Construction

- Conductor: Typically copper or aluminum, stranded for flexibility

- Insulation: PVC (Polyvinyl Chloride) rated for 0.6/1kV applications

- Bedding: PVC compound protecting the insulated cores

- Armour: Galvanized steel wires providing mechanical protection

- Outer Sheath: PVC compound resistant to water, chemicals, and UV exposure

Standard Specifications

- Voltage Rating: 0.6/1kV (600/1000V)

- Temperature Range: -15°C to +70°C operational temperature

- Bending Radius: Minimum 12 times the overall diameter when installed

- Standards Compliance: IEC 60502, BS 5467, GB/T 12706, and other international standards

Key Features and Benefits of VV32 Cable

Superior Mechanical Protection

The steel wire armour in VV32 cables provides exceptional resistance against crushing forces, impact damage, and rodent attacks. This makes it particularly valuable in installations where cables may be exposed to physical hazards.

Enhanced Environmental Resistance

VV32 armoured cables excel in challenging environments:

- Water and moisture resistance (suitable for direct burial)

- Resistance to oils, chemicals, and solvents

- UV stability for outdoor applications

- Protection against temperature fluctuations

Operational Reliability

The robust construction ensures consistent electrical performance even under demanding conditions:

- Reduced risk of short circuits and electrical failures

- Longer service life compared to non-armoured alternatives

- Minimal maintenance requirements

- Stable performance under load variations

Installation Flexibility

Despite its rugged construction, VV32 cable maintains adequate flexibility for practical installation:

- Can be installed in trays, ducts, or directly buried

- Suitable for vertical and horizontal runs

- Adaptable to confined spaces with proper bending radius

Common Applications of VV32 Armoured Power Cable

Industrial Facilities

- Manufacturing plants and production lines

- Heavy machinery power connections

- Industrial automation systems

- Power distribution between buildings

Infrastructure Projects

- Underground power distribution networks

- Railway signaling and power systems

- Tunnel lighting and ventilation systems

- Bridge and highway infrastructure

Commercial and Utility Applications

- Shopping centers and large commercial complexes

- Water treatment facilities

- Power stations and substations

- Mining operations and extraction equipment

Specialized Environments

- Marine and offshore installations

- Agricultural facilities with high rodent activity

- Areas with high risk of mechanical damage

- Temporary power distribution in construction sites

Installation Guidelines for VV32 Cable

Pre-Installation Planning

- Calculate voltage drop based on load requirements and cable length

- Verify compatibility with termination equipment

- Plan cable routes to minimize sharp bends

- Ensure adequate pulling tension limits are maintained

Termination Best Practices

- Use appropriate gland fittings designed for armoured cables

- Properly earth the steel armour at both ends

- Maintain insulation integrity during termination

- Follow manufacturer specifications for sealing against moisture ingress

Safety Considerations

- Always de-energize circuits before installation or maintenance

- Use proper PPE when handling armoured cables

- Verify earth continuity of the steel armour

- Follow local electrical codes and regulations

VV32 vs. Other Armoured Cable Types: Making the Right Choice

When selecting armoured cables, understanding the differences between variants is crucial:

| Feature | VV32 | VV22 | YJV32 | VV42 |

|---|---|---|---|---|

| Armour Type | Fine steel wires | Steel tape | Fine steel wires | Coarse steel wires |

| Flexibility | High | Moderate | High | Low |

| Crushing Resistance | Excellent | Good | Excellent | Superior |

| Tensile Strength | Excellent | Moderate | Excellent | Excellent |

| Typical Application | Vertical runs, high tensile stress | General purpose | Vertical runs, high performance | Heavy industrial, extreme conditions |

How to Select the Right VV32 Cable for Your Project

Consider These Critical Factors:

- Current Carrying Capacity: Calculate the required ampacity based on load requirements, ambient temperature, and installation method.

- Environmental Conditions: Assess exposure to water, chemicals, UV radiation, and temperature extremes.

- Mechanical Stress: Evaluate potential crushing forces, impact risks, and tensile loads the cable may experience.

- Installation Method: Consider whether the cable will be buried directly, installed in ducts, or run vertically.

- Regulatory Requirements: Ensure compliance with local electrical codes and industry standards.

- Future Expansion: Allow some capacity headroom for potential load increases.

Maintenance Tips for Long-Term Performance

- Schedule regular inspections for sheath damage, especially at terminations

- Test insulation resistance annually or as per facility maintenance protocols

- Check armour earth continuity periodically

- Monitor for signs of overheating at connections and terminations

- Keep cable routes clear of debris that could trap moisture or cause damage