When reliability and durability are non-negotiable in electrical power distribution, Cu/XLPE/PVC/AWA/PVC armoured power cables stand as the industry gold standard. These multi-layered cables deliver exceptional performance in the most demanding environments, from underground installations to industrial plants exposed to mechanical stress and harsh conditions. This comprehensive guide explores why electrical engineers, contractors, and procurement specialists choose this specific cable configuration for mission-critical applications worldwide.

Understanding Cu/XLPE/PVC/AWA/PVC Cable Construction

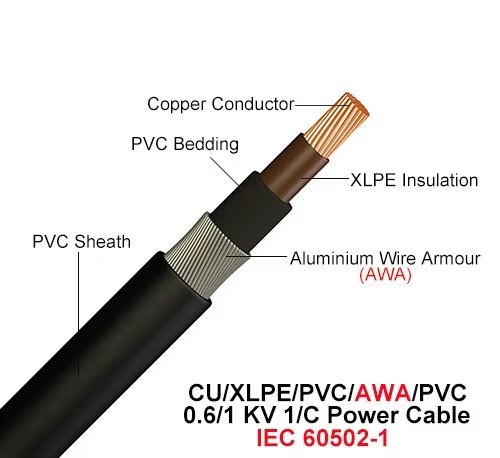

The designation “Cu/XLPE/PVC/AWA/PVC” precisely describes this cable’s layered construction:

- Cu (Copper Conductor): High-purity copper conductors provide excellent electrical conductivity, flexibility, and resistance to fatigue. Available in stranded or solid configurations depending on application requirements.

- XLPE (Cross-Linked Polyethylene Insulation): Superior thermal properties (90°C operating temperature) compared to standard PVC insulation, with excellent electrical characteristics and resistance to environmental stress.

- PVC (Inner Sheath): Provides a protective barrier between the insulation and armor, preventing damage during installation and service.

- AWA (Aluminum Wire Armor): Interlocked aluminum wire armor delivers exceptional mechanical protection against impact, crushing forces, and rodent damage while maintaining flexibility.

- PVC (Outer Sheath): Final protective layer resistant to oil, chemicals, UV exposure, and abrasion, available in various colors for circuit identification.

This five-layer construction creates a cable that balances electrical performance with unmatched physical protection.

Technical Specifications and Performance Ratings

| Parameter | Specification | Details |

|---|---|---|

| Voltage Rating | 0.6/1kV or 1.9/3.3kV | Suitable for low and medium voltage distribution |

| Conductor Size Range | 1.5mm² to 400mm² | Adaptable for various current loads |

| Operating Temperature | -15°C to +90°C | XLPE insulation enables higher temperature operation |

| Short Circuit Rating | 250°C max | Withstands fault conditions without immediate failure |

| Bending Radius | 12× overall diameter | Maintains integrity during installation in tight spaces |

| Compliance Standards | IEC 60502, BS 5467, ICEA S-95-658 | Meets international quality benchmarks |

Key Applications for Cu/XLPE/PVC/AWA/PVC Armoured Cables

These robust cables excel in demanding environments:

- Underground Power Distribution: Direct burial installations benefit from the mechanical protection against soil pressure, rocks, and excavation activities.

- Industrial Facilities: Manufacturing plants, refineries, and processing facilities where cables face exposure to oils, chemicals, and physical hazards.

- Mining Operations: Withstands extreme mechanical stresses, moisture, and hazardous conditions underground and on the surface.

- Infrastructure Projects: Transportation systems, utility networks, and public works requiring decades of maintenance-free service.

- Renewable Energy Installations: Solar farms and wind power facilities exposed to weather extremes and requiring high reliability.

Installation Best Practices for Maximum Performance

Proper installation ensures these premium cables deliver their full service life:

- Planning the Route: Map cable paths to minimize bends and avoid sharp edges that could damage the outer sheath during pulling.

- Tension Management: Use appropriate pulling grips on the armor (not the conductors) and monitor pulling tension with calibrated equipment.

- Bending Radius Compliance: Maintain minimum bending radius during installation to prevent internal damage to conductors and insulation.

- Termination Techniques: Strip layers carefully using specialized tools, ensure proper gland selection for armored cable entries, and follow manufacturer termination procedures.

- Testing Protocol: Perform insulation resistance testing (minimum 100 MΩ/km at 500V DC) and continuity checks before energizing circuits.

Why Choose Armoured Cable Over Non-Armoured Alternatives?

While non-armoured cables may cost less initially, Cu/XLPE/PVC/AWA/PVC armoured cables deliver superior value through:

- Extended Service Life: Properly installed armoured cables often exceed 30 years of service in challenging environments.

- Reduced Maintenance Costs: The armor protection minimizes damage incidents requiring costly repairs and downtime.

- Enhanced Safety Profile: Mechanical protection reduces risk of electrical faults, short circuits, and fire hazards.

- Total Cost of Ownership: When factoring installation labor, protection conduit requirements, and replacement frequency, armoured cables often prove more economical long-term.

Frequently Asked Questions

Q: What’s the difference between AWA (Aluminum Wire Armor) and SWA (Steel Wire Armor)?

A: AWA (Aluminum Wire Armor) offers lighter weight and non-magnetic properties ideal for single-core cables where steel would cause eddy current losses. SWA (Steel Wire Armor) provides superior crush resistance but is heavier and unsuitable for AC single-core applications due to electromagnetic effects.

Q: Can Cu/XLPE/PVC/AWA/PVC cables be installed in water or continuously wet locations?

A: Yes, these cables are suitable for direct burial and wet locations. The XLPE insulation is water-resistant, and the armor plus PVC sheath creates an effective moisture barrier. For permanent submersion, however, specialized water-blocking variants may be recommended.

Q: How do I determine the correct cable size for my application?

A: Cable sizing depends on load current, ambient temperature, installation method, and allowable voltage drop. Always consult relevant standards (IEC 60364-5-52) or use professional cable calculation software, considering both normal operation and short-circuit performance requirements.

Q: What color options are available for the outer PVC sheath?

A: Black is standard for most industrial applications, but red, blue, grey, and other colors are available for circuit identification purposes. Special color coding helps maintenance teams quickly identify critical circuits during operations and repairs.