What Is YJV Power Cable and Why It Matters for Your Electrical Projects

When selecting the right power cable for industrial, commercial, or residential applications, understanding your options is crucial for safety, efficiency, and cost-effectiveness. Among the most widely used power transmission solutions globally, YJV power cable stands out as a reliable choice for fixed installations across diverse environments. This comprehensive guide explores everything electrical professionals and procurement managers need to know about YJV cables to make informed decisions for their projects.

Understanding YJV Cable Construction and Design

YJV power cable represents a specific construction standard in the electrical industry. The designation “YJV” contains important information about the cable’s composition:

- Y: Polyethylene (PE) or PVC outer sheath

- J: Cross-linked polyethylene (XLPE) insulation

- V: PVC sheath

This standardized naming convention helps professionals quickly identify the cable’s key properties and suitability for specific applications.

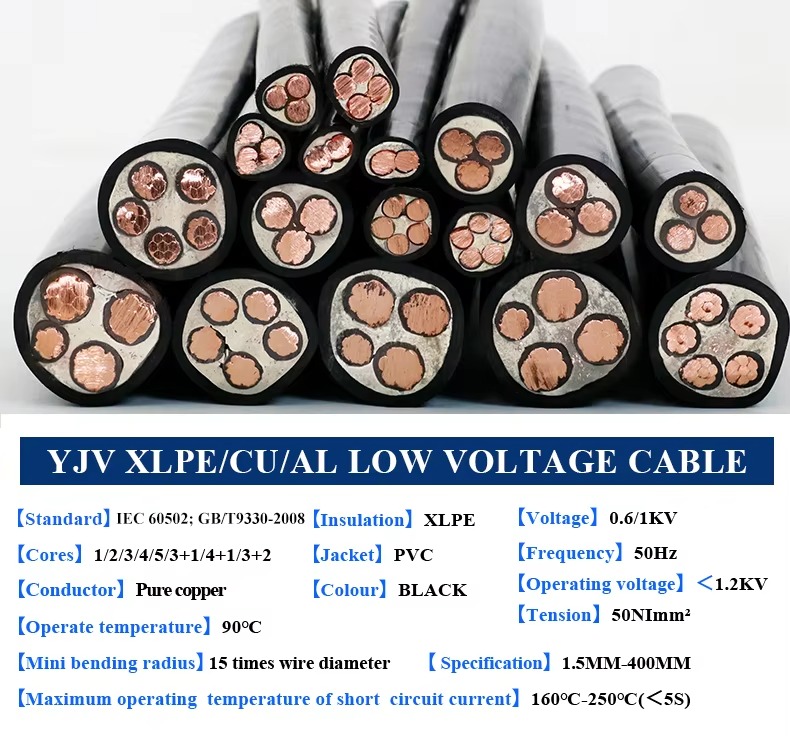

Core Components of YJV Power Cable

A typical YJV cable consists of several essential components working together to ensure optimal performance:

- Conductor: Usually made of copper (YJV) or aluminum (YJLV), available in various cross-sections from 1.5mm² to 1000mm²

- Insulation: XLPE (cross-linked polyethylene) provides excellent electrical properties and thermal resistance

- Filler: Non-hygroscopic material that maintains the cable’s circular shape

- Sheath: PVC outer layer offering mechanical protection and environmental resistance

Technical Specifications and Performance Characteristics

Voltage Ratings and Temperature Performance

YJV power cables are primarily designed for fixed installations with rated voltages of:

- 0.6/1kV for low voltage applications

- 3.6/6kV, 6/10kV, 8.7/15kV, 12/20kV, 18/30kV for medium voltage applications

The XLPE insulation enables these cables to operate continuously at temperatures up to 90°C, with short-circuit temperatures reaching 250°C for brief periods. This thermal performance makes YJV cables suitable for high-load applications where heat generation is significant.

Electrical and Mechanical Properties

YJV cables demonstrate impressive performance characteristics:

- Excellent electrical conductivity with minimal power loss

- High resistance to electrical treeing and water penetration

- Good flame retardant properties (depending on specific variants)

- Flexibility for easier installation in tight spaces

- Resistance to oils, chemicals, and UV exposure (in specialized variants)

Common Applications of YJV Power Cables

The versatility of YJV power cables makes them suitable for numerous applications across multiple industries:

Industrial Applications

- Power distribution within manufacturing facilities

- Connection of heavy machinery and equipment

- Underground installations in industrial complexes

- Power supply to production lines requiring reliable energy transmission

Commercial and Infrastructure Uses

- Building wiring for high-rise structures

- Shopping centers and commercial complexes

- Hospital and healthcare facility electrical systems

- Airport and transportation hub power distribution

Utility and Energy Sector

- Power transmission between substations

- Renewable energy installations (solar farms, wind farms)

- Urban power distribution networks

- Mining operations requiring durable underground cabling

YJV vs. Other Power Cable Types: Making the Right Choice

Understanding how YJV compares to alternative cable types helps in selecting the optimal solution:

YJV vs. VV Cables

While VV cables use PVC insulation, YJV’s XLPE insulation offers superior thermal stability, allowing higher current capacity and longer service life. YJV cables can operate at 90°C compared to VV’s limit of 70°C.

YJV vs. YJY Cables

The primary difference is in the sheath material—YJV uses PVC sheathing while YJY uses polyethylene. YJV offers better flame resistance, while YJY provides enhanced moisture resistance for direct burial applications.

YJV vs. YJV22 Armored Cables

Standard YJV lacks mechanical protection, while YJV22 includes steel tape armor for applications requiring enhanced protection against physical damage, rodent attacks, or direct burial without conduit.

Installation Best Practices for YJV Power Cables

Proper installation significantly impacts the performance and lifespan of YJV power cables. Consider these critical guidelines:

Pre-Installation Considerations

- Verify cable specifications match your project requirements

- Check environmental conditions including temperature extremes, moisture levels, and chemical exposure

- Ensure adequate bending radius (typically 15× cable diameter for single-core, 12× for multi-core)

- Plan cable routes to minimize exposure to heat sources and physical hazards

Installation Process

- Use appropriate pulling grips and tension monitors during cable pulling

- Maintain minimum bending radius throughout installation

- Provide adequate support with approved cable cleats or trays

- Ensure proper separation from communication cables to prevent interference

- Follow local electrical codes for burial depth if installing underground

Safety Considerations and Compliance Standards

YJV power cables must meet stringent safety standards to ensure reliable operation:

- IEC 60502: International standard for power cables up to 30kV

- GB/T 12706: Chinese national standard for extruded insulated power cables

- UL 44: Safety standard for thermoset-insulated wires and cables

- RoHS compliance: Ensuring cables are free from hazardous substances

Always verify that your YJV cables carry appropriate certification marks from recognized testing organizations before installation.

Maintenance and Troubleshooting Common Issues

While YJV cables are designed for longevity, proper maintenance extends service life:

Routine Inspection Points

- Check for physical damage to the outer sheath

- Monitor connections for signs of overheating

- Inspect cable supports for integrity

- Test insulation resistance periodically

Common Issues and Solutions

- Overheating: Ensure adequate derating in high-ambient temperature environments

- Moisture ingress: Verify proper sealing at terminations and joints

- Electromagnetic interference: Maintain separation from sensitive equipment or use shielded variants

- Premature aging: Replace cables exposed to continuous temperatures beyond rated capacity

Frequently Asked Questions About YJV Power Cables

What does YJV stand for in power cables?

YJV designates a specific cable construction: Y indicates polyethylene or PVC sheath, J represents XLPE insulation, and V signifies PVC sheathing.

Can YJV cables be installed underground?

Standard YJV cables require protection when buried underground. For direct burial applications, consider armored variants like YJV22 or YJV32, which include steel tape or wire armor for mechanical protection.

What’s the maximum operating temperature for YJV cables?

YJV power cables with XLPE insulation can operate continuously at temperatures up to 90°C, significantly higher than PVC-insulated alternatives.

How do I determine the correct cable size for my application?

Cable sizing depends on load current, installation method, ambient temperature, and allowable voltage drop. Always consult relevant standards and consider consulting a qualified electrical engineer for critical applications.

Are YJV cables fire-resistant?

Standard YJV cables have basic flame-retardant properties. For enhanced fire performance, consider specialized variants like YJV-ZR (flame-retardant) or YJV-WDZ (low-smoke zero-halogen) cables.