What Are Steel Wire Armored (SWA) Power Cables?

Steel Wire Armored (SWA) electric power cables are heavy-duty cables designed for maximum mechanical protection and durability. Featuring a robust layer of galvanized steel wires wrapped around the insulated conductors, SWA cables withstand crushing forces, rodent attacks, and harsh environmental conditions. Commonly used in underground, industrial, and external power distribution systems, they comply with international standards like IEC 60502, BS 5467, and IEC 60228.

Whether you’re an electrical engineer, contractor, or procurement specialist, understanding SWA cables ensures reliable power transmission in demanding scenarios.

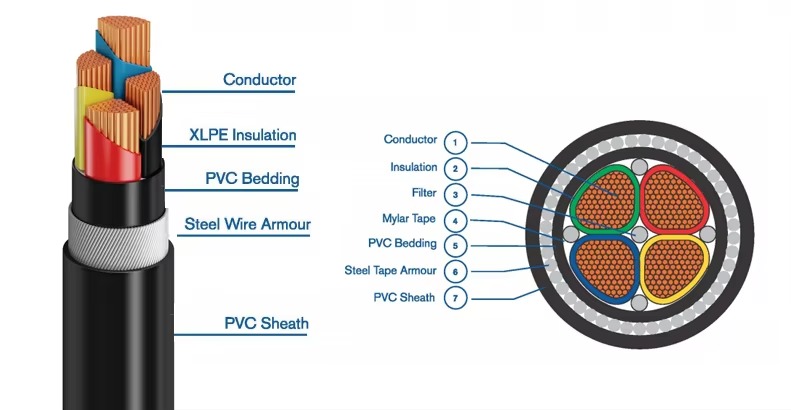

How SWA Cables Are Constructed: Layers of Protection

A typical SWA cable comprises multiple layers engineered for safety and longevity:

- Conductor: Stranded copper or aluminum (Class 2 per IEC 60228) for flexibility and conductivity.

- Insulation: Cross-linked polyethylene (XLPE) or PVC for thermal stability and electrical resistance.

- Bedding: A PVC or PE sheath cushioning the armor layer.

- Armor: Interlocked galvanized steel wires providing crush resistance and tensile strength.

- Outer Sheath: UV-resistant PVC or LSZH (Low Smoke Zero Halogen) material for environmental protection.

This multi-layer design makes SWA cables ideal for direct burial, trench installations, and high-risk zones like construction sites or chemical plants.

Top Applications of SWA Cables

SWA cables excel in environments where standard cables would fail:

- Underground Power Distribution: Resistant to soil pressure, moisture, and accidental excavation damage.

- Industrial Facilities: Withstand vibrations, heavy machinery, and extreme temperatures in factories and mines.

- Renewable Energy Projects: Connect solar farms and wind turbines exposed to weather extremes.

- Public Infrastructure: Used in street lighting, railways, and utility networks requiring fire-resistant options (LSZH variants).

- Marine & Offshore Installations: Corrosion-resistant versions protect against saltwater exposure.

5 Key Advantages of Steel Wire Armored Cables

1. Unmatched Mechanical Strength

The steel armor layer absorbs physical impacts, making SWA cables 3x more durable than non-armored alternatives.

2. Enhanced Safety Compliance

Meets fire safety standards (e.g., IEC 60332-1 for flame retardancy) and reduces short-circuit risks through robust grounding.

3. Long-Term Cost Efficiency

Despite higher upfront costs, SWA cables last 25+ years with minimal maintenance, reducing replacement expenses.

4. Versatile Voltage Ratings

Available for low-voltage (0.6/1 kV) to high-voltage (up to 33 kV) applications.

5. Eco-Friendly Options

LSZH-sheathed SWA cables emit non-toxic fumes during fires, complying with green building regulations.

How to Choose the Right SWA Cable: A Practical Checklist

Selecting the wrong cable risks system failure. Ask these questions before purchasing:

✅ Environment: Will it face moisture, chemicals, or extreme temperatures? Opt for PE sheathing in wet conditions.

✅ Voltage Requirements: Match cable rating to your system (e.g., 600/1000V for industrial machinery).

✅ Conductor Material: Copper offers superior conductivity; aluminum is lighter and cost-effective for long runs.

✅ Fire Safety: Use LSZH cables in tunnels, hospitals, or public spaces.

✅ Certifications: Verify compliance with local standards (e.g., BASEC approval in the UK, UL listing in the US).

Pro Tip: For direct burial, choose SWA cables with water-blocking tapes to prevent moisture ingress.

Installation Best Practices for SWA Cables

Improper installation compromises even the highest-quality cables. Follow these guidelines:

- Bending Radius: Maintain a minimum bend radius of 12x the cable diameter to avoid armor damage.

- Grounding: Bond the steel armor to earth at both ends to prevent induced currents.

- Trench Depth: Bury cables at least 0.7m deep (per IEC 61914) with warning tape placed 300mm above.

- Pulling Tension: Use swivel grips and lubricants to reduce stress during installation.

- Jointing: Employ heat-shrink kits rated for armored cables to maintain IP68 protection.

SWA vs. AWA Cables: Which Is Right for Your Project?

While SWA cables use steel wire armor, Aluminum Wire Armored (AWA) variants offer lighter weight and corrosion resistance. Key differences:

| Factor | SWA Cable | AWA Cable |

|---|---|---|

| Strength | Higher crush resistance | Moderate protection |

| Weight | Heavier | 30% lighter |

| Corrosion | Requires galvanization | Naturally corrosion-proof |

| Cost | Lower material cost | Premium pricing |

| Best For | Underground, industrial | Coastal areas, indoor use |

Choose SWA for rugged outdoor use; AWA suits corrosive or weight-sensitive projects.

Maintenance & Safety: Extending SWA Cable Lifespan

- Inspection: Check for sheath damage, corrosion, or deformation every 6 months.

- Thermal Imaging: Detect hotspots caused by loose armor grounding.

- Load Management: Avoid overloading to prevent insulation degradation.

- Repair Protocol: Replace damaged sections immediately—never patch armor layers.

Frequently Asked Questions (FAQs)

Q1: Can SWA cables be installed underwater?

Yes, but only if rated for submersion (e.g., with polyethylene sheathing). Standard PVC-sheathed SWA cables are not waterproof.

Q2: Is SWA cable suitable for indoor use?

Absolutely—for risers, basements, or areas requiring fire resistance. Use LSZH-sheathed variants indoors to meet fire codes.

Q3: How deep should SWA cables be buried?

Minimum 0.7 meters (27 inches) in most regions. Add concrete encasement in high-traffic areas.

Q4: Can I join two SWA cables?

Yes, using armored cable joint kits with earth continuity bridges. Always hire a licensed electrician for connections.

Q5: What’s the maximum operating temperature for XLPE-insulated SWA cables?

90°C under load, with short-circuit tolerance up to 250°C for 5 seconds.