What Is a Flat Underwater Waterproof Rubber Cable?

A flat underwater waterproof rubber cable is a specialized electrical conductor designed specifically for permanent or temporary submersion in water. Unlike traditional round cables, its flattened profile provides unique advantages in underwater applications, including reduced water resistance, easier installation in tight spaces, and superior resistance to movement caused by currents.

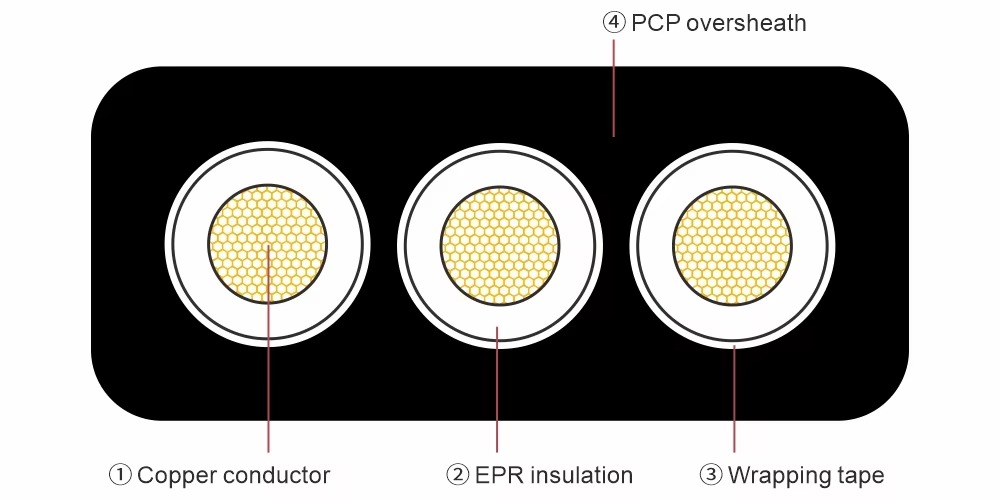

These cables feature multiple layers of protection:

- Inner conductor: Typically made of finely stranded copper for maximum flexibility

- Insulation layer: Special rubber compound resistant to water penetration

- Reinforcement layer: Often includes textile or synthetic strength members

- Outer sheath: Heavy-duty rubber formulation designed specifically for underwater use

Key Technical Specifications to Consider

Conductor Material & Configuration

High-quality flat underwater cables use tinned copper conductors that resist corrosion in wet environments. The flat configuration typically contains 2-5 conductors arranged side by side, providing a low-profile design that minimizes water resistance.

Insulation Materials

Premium underwater cables utilize specialized rubber compounds including:

- EPDM (Ethylene Propylene Diene Monomer): Excellent resistance to water, heat, and weathering

- Neoprene: Superior flexibility and resistance to oil, chemicals, and abrasion

- CSPE (Chlorosulfonated Polyethylene): Exceptional performance in harsh aquatic environments

Voltage Rating & Current Capacity

Most flat underwater cables are rated for 300/500V applications, with current capacities ranging from 3A to 32A depending on conductor size (typically 0.75mm² to 10mm² cross-sections).

Temperature Range & Pressure Resistance

Quality cables maintain performance in temperatures from -40°C to +90°C and withstand significant water pressure, making them suitable for depths exceeding 100 meters in some specialized variants.

Applications of Flat Underwater Waterproof Rubber Cables

Marine & Boating Applications

- Navigation light connections

- Underwater hull lighting systems

- Sonar and fish finder installations

- Marine pump connections

Aquaculture & Fisheries

- Aeration system power supplies

- Monitoring equipment connections

- Underwater camera systems

- Automated feeding mechanisms

Recreational Water Features

- Swimming pool lighting systems

- Fountain and waterfall pumps

- Pond filtration systems

- Decorative underwater lighting

Industrial & Municipal Uses

- Wastewater treatment plant equipment

- Hydroelectric monitoring systems

- Dock and harbor lighting

- Submersible pump installations

10 Critical Advantages of Flat Submersible Rubber Cables

Unlike conventional round cables, flat underwater waterproof rubber cables offer distinct advantages that make them the preferred choice for aquatic electrical installations:

- Reduced Water Resistance: The streamlined flat profile minimizes drag and movement in currents

- Superior Flexibility: Multiple thin conductors allow for easier routing in confined underwater spaces

- Enhanced Durability: Special rubber compounds resist degradation from constant water exposure

- UV Resistance: Formulated to withstand prolonged exposure to sunlight when partially exposed

- Chemical Resistance: Withstands exposure to chlorine, salt, and other aquatic chemicals

- Abrasion Resistance: Tough outer sheath protects against rocks, concrete, and sharp edges

- Oil & Fuel Resistance: Essential for marine applications near engines or fuel sources

- Cold Temperature Flexibility: Remains pliable in cold water environments where PVC would harden

- Long Service Life: Quality flat underwater cables last 5-10 years in permanent submersion

- Safety Certification: Properly rated cables meet international marine safety standards

Installation Best Practices for Maximum Performance

Pre-Installation Considerations

Before deploying your flat underwater waterproof rubber cable, carefully plan the routing to minimize stress points and exposure to potential damage. Always use cables specifically rated for continuous submersion—not merely water-resistant cables designed for damp locations.

Connection & Termination Techniques

- Use waterproof cable glands rated for underwater use

- Apply self-amalgamating tape to connections before heat shrink application

- Ensure all terminations are positioned above water level when possible

- Allow sufficient service loops for maintenance without stressing connections

Securing Methods

- Use UV-resistant cable ties designed for underwater use

- Install protective conduit where cables cross sharp edges

- Maintain a minimum bending radius of 6× the cable width

- Avoid tension points that could compromise the waterproof integrity

Testing Procedures

Before final deployment, test the installation with:

- Megger insulation resistance testing (minimum 100 MΩ)

- Continuity checks for all conductors

- Polarity verification

- Load testing under water to confirm no leakage

Safety Standards & Certifications to Look For

When specifying flat underwater waterproof rubber cables, ensure they carry appropriate certifications:

- UL 1581: Standard for vertical tray flame tests

- CSA FT4: Canadian flame test requirements

- IEC 60502: International standard for power cables

- UL 1277: Standard for tray cables

- Marine certifications: UL 157, DNV GL, Lloyd’s Register, or ABS for marine applications

- IP ratings: Minimum IP68 for continuous submersion

Maintenance & Troubleshooting Guide

Even the highest quality flat underwater cables require periodic inspection and maintenance:

Inspection Schedule

- Visual inspection before each seasonal use

- Comprehensive testing every 12 months for permanent installations

- Immediate inspection after lightning strikes or electrical anomalies

Common Issues & Solutions

- Abrasion damage: Replace affected sections; add protective conduit

- Termination failures: Re-terminate using proper waterproofing techniques

- Conductor corrosion: Cut back to good conductor; use dielectric grease on connections

- Sheath hardening: Replace cable if flexibility is compromised

- Swelling: Indicates water ingress; replace affected sections immediately

Frequently Asked Questions

Can flat underwater cables be joined underwater?

While specialized underwater junction boxes exist, it’s best practice to make all connections above water. If underwater connections are unavoidable, use only purpose-built wet-mate connectors rated for permanent submersion.

How deep can these cables operate?

Standard flat underwater rubber cables are typically rated for depths up to 50 meters. For deeper applications, specialized cables with enhanced pressure resistance are available.

What’s the expected lifespan of quality underwater cables?

With proper installation and maintenance, premium flat underwater waterproof rubber cables typically last 5-10 years in continuous submersion applications. Exposure to sunlight, chemicals, or mechanical stress can reduce this timeframe.

Can these cables be used in saltwater applications?

Yes, but ensure the specific cable is rated for saltwater use. Saltwater requires enhanced corrosion protection for conductors and special jacket compounds resistant to salt degradation.

How do temperature extremes affect performance?

Quality flat underwater rubber cables maintain flexibility and performance in temperatures from -40°C to +90°C, making them suitable for most global aquatic environments.