When it comes to demanding electrical applications requiring exceptional flexibility and durability, the H07RN-F rubber insulated flexible power cable stands as an industry benchmark. This versatile cable solution combines robust construction with remarkable performance characteristics, making it the preferred choice for professionals across multiple sectors. In this comprehensive guide, we’ll explore everything you need to know about H07RN-F cables, from technical specifications to real-world applications.

What is H07RN-F Cable?

H07RN-F is a harmonized flexible rubber-sheathed cable designed for heavy-duty applications where standard PVC cables would fail. The designation “H07RN-F” follows European harmonization standards, where:

- “H” indicates harmonized cable

- “07” refers to the voltage rating (450/750V)

- “R” stands for rubber insulation

- “N” indicates rubber or thermoplastic elastomer sheathing resistant to oil and weather

- “F” denotes high flexibility

Technical Specifications & Construction

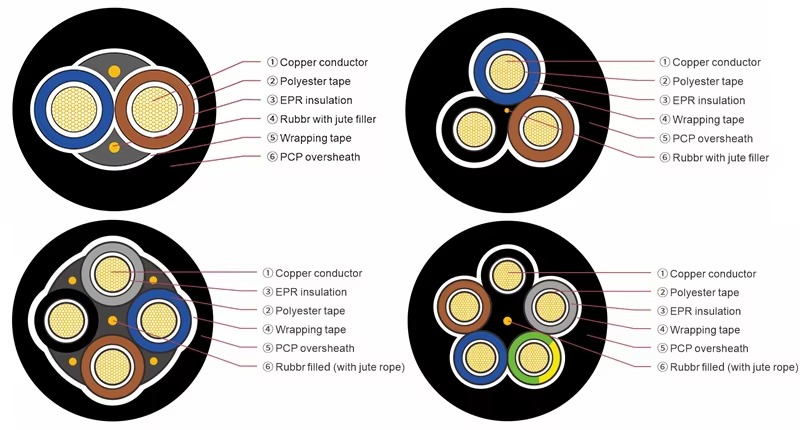

Core Components

- Conductor: High-quality fine-stranded pure copper (class 5 flexible conductors according to IEC 60228)

- Insulation: Ethylene Propylene Diene Monomer (EPDM) rubber

- Sheath: Chlorinated Polyethylene (CPE) rubber compound

- Available Sizes: 1.5mm², 2.5mm², 4mm², 6mm², 10mm², 16mm², 25mm², 35mm², 50mm², 70mm², 95mm², and larger cross-sections

- Core Configuration: Available from 2-core to 5-core configurations

Performance Parameters

- Voltage Rating: 450/750V AC

- Maximum Operating Temperature: +90°C

- Minimum Installation Temperature: -25°C

- Minimum Fixed Bending Radius: 6× overall diameter

- Operating Temperature Range: -40°C to +90°C (fixed installation)

Key Features & Advantages

Superior Environmental Resistance

H07RN-F cables excel where other cables fail due to their exceptional resistance properties:

- Weather & UV Resistant: Ideal for prolonged outdoor exposure

- Oil & Chemical Resistant: Withstands exposure to oils, greases, and many industrial chemicals

- Water & Moisture Resistant: Suitable for wet environments and occasional submersion

- Flame Retardant: Self-extinguishing properties enhance safety

Mechanical Durability

- High Flexibility: Withstands repeated bending and movement without damage

- Abrasion Resistant: Tough rubber sheath protects against physical damage

- Cold Resistant: Remains flexible even in extremely low temperatures

- Anti-Aging Properties: Extended service life even in harsh conditions

Common Applications

H07RN-F rubber cables are the go-to solution for numerous demanding applications:

Industrial & Construction

- Construction sites and temporary power distribution

- Portable tools and equipment in industrial environments

- Material handling systems and automated machinery

- Mining equipment and harsh industrial environments

Entertainment & Events

- Stage lighting and audio equipment

- Outdoor event power distribution

- Film and television production equipment

- Temporary installations requiring frequent relocation

Infrastructure & Utilities

- Port areas and maritime applications

- Water treatment facilities

- Temporary power installations at dams and hydroelectric sites

- Emergency power systems

Commercial & Residential

- LED lighting systems (indoor and outdoor)

- Swimming pool and garden equipment

- HVAC systems requiring flexible connections

- High-end appliance wiring (ovens, pressure cookers, etc.)

Installation Guidelines & Safety Considerations

Best Practices

- Ensure proper cable sizing based on load requirements and voltage drop calculations

- Maintain minimum bending radius during installation to prevent damage

- Use appropriate cable glands and connectors rated for rubber cables

- Avoid sharp edges and pinch points that could damage the sheath

- Secure cables properly to prevent excessive movement or strain

Certification & Compliance

H07RN-F cables typically carry multiple certifications including:

- VDE (Germany)

- CE marking (European conformity)

- RoHS compliance

- REACH compliance

- Various national and international standards (IEC, EN)

How to Select the Right H07RN-F Cable

Choosing the appropriate H07RN-F cable requires consideration of several factors:

- Determine Required Current Capacity: Calculate the expected load and select conductor size accordingly

- Assess Environmental Conditions: Consider temperature extremes, exposure to oils/chemicals, UV exposure

- Number of Cores Needed: Match core count to your equipment requirements (2-core, 3-core, 4-core, or 5-core)

- Verify Certification Requirements: Ensure the cable meets regulatory requirements for your region and application

- Consider Mechanical Stress: For highly dynamic applications, verify the cable’s flex rating is adequate

H07RN-F vs. Alternative Flexible Cables

| Feature | H07RN-F | H05RN-F | PVC Flexible Cables |

|---|---|---|---|

| Voltage Rating | 450/750V | 300/500V | Typically 300/500V |

| Temperature Range | -40°C to +90°C | -25°C to +80°C | -5°C to +70°C |

| Oil Resistance | Excellent | Good | Poor to Fair |

| UV Resistance | Excellent | Good | Fair to Poor |

| Flexibility | Excellent | Excellent | Good |

| Typical Applications | Heavy-duty industrial | Light to medium duty | General purpose indoor |

Maintenance & Service Life

With proper installation and use within specifications, H07RN-F cables typically provide 10-15 years of reliable service. To maximize lifespan:

- Periodically inspect for physical damage, especially at connection points

- Check for signs of overheating (discoloration, hardening of rubber)

- Replace cables showing cracks, excessive wear, or damaged insulation

- Store spare cable in cool, dry conditions away from direct sunlight

Frequently Asked Questions

Q: Can H07RN-F cable be used permanently outdoors? A: Yes, H07RN-F is specifically designed for outdoor use with excellent UV and weather resistance. It’s suitable for permanent outdoor installations.

Q: Is H07RN-F cable suitable for direct burial? A: While H07RN-F has good water resistance, it’s not specifically designed for direct burial. It should be installed in conduit or cable ducting when buried underground.

Q: How does H07RN-F compare to SOOW cable? A: H07RN-F is the European harmonized equivalent to North American SOOW cable. Both offer similar performance characteristics with rubber insulation and oil-resistant jackets.

Q: What’s the difference between H07RN-F and H05RN-F? A: H07RN-F is rated for higher voltage (450/750V vs 300/500V) and generally has better temperature resistance and mechanical properties than H05RN-F.

Q: Can H07RN-F cable be used in food processing environments? A: Standard H07RN-F is not certified for direct food contact. Special variants with food-grade rubber compounds are available for food processing applications.