KVV control cables

Reply Quickly

7 Days Fast Delivery

High Praise Rate

Zero Complaints & incidents

KVV control cables represent one of the most widely used cable types in industrial automation, electrical control systems, and instrumentation applications worldwide. These versatile polyvinyl chloride (PVC) insulated and sheathed cables are specifically engineered for control, monitoring, and protection circuits in electrical installations. This comprehensive guide explores the technical specifications, variants, applications, and selection criteria for KVV control cables to help electrical engineers and procurement professionals make informed decisions.

What Is KVV Control Cable?

KVV control cable is a multi-core cable designed for transmitting control signals and electrical power in control systems where voltages do not exceed 450/750V. The designation “KVV” follows Chinese cable naming conventions where:

- K = Control cable

- V = PVC insulation

- V = PVC sheath

Manufactured according to international standards including GB9330, IEC60227, and IEC60502, these cables provide reliable performance in demanding industrial environments while maintaining cost-effectiveness.

Technical Specifications and Construction

Core Construction

- Conductor: Electrolytic copper, available in solid (Class 1) or stranded (Class 2, typically 7-wire) configurations

- Insulation: PVC compound with color coding for easy identification

- Core Arrangement: Cores laid up in layers with optional fillers to maintain circular shape

- Outer Sheath: Robust PVC compound providing mechanical and environmental protection

Electrical Properties

- Rated Voltage: 450/750V AC or 1000V DC

- Maximum Conductor Temperature: 70°C during normal operation

- Test Voltage: Typically 2500V for 5 minutes

- Insulation Resistance: ≥100 MΩ·km at 20°C

Mechanical and Environmental Properties

- Minimum Bending Radius:

- 6× overall diameter for unarmored cables

- 12× overall diameter for armored or shielded variants

- Installation Temperature: Not below 0°C

- Operating Temperature Range: -15°C to +70°C

- Flame Retardancy: Standard versions meet basic flame retardant requirements; special variants available with enhanced fire performance

KVV Cable Variants and Their Applications

KVV control cables come in numerous variants to address specific application requirements:

| Cable Type | Construction Features | Typical Applications |

|---|---|---|

| KVV | Basic PVC insulated and sheathed | General control circuits in protected environments |

| KVVP | Copper wire braid shielding | Environments with electromagnetic interference (EMI) concerns |

| KVVR | Flexible construction | Moving equipment, robotic systems, applications requiring frequent bending |

| KVVRP | Flexible with copper braid shielding | EMI-prone environments requiring cable flexibility |

| KVVP2 | Copper tape shielding | High-sensitivity instrumentation, critical control systems |

| KVV22 | Steel tape armored | Underground installation, areas with mechanical stress risk |

| KVV32 | Steel wire armored | Vertical installations, applications requiring tensile strength |

Installation Guidelines

Proper installation is critical to ensure optimal performance and longevity of KVV control cables:

- Routing Considerations: Keep control cables separate from power cables to minimize interference; minimum separation of 300mm recommended

- Bending Requirements: Never exceed minimum bending radius specifications during installation

- Pulling Tension: Maximum pulling tension should not exceed 15N/mm² of conductor cross-section

- Fixing Intervals: Secure cables at intervals not exceeding 400mm for horizontal runs and 1000mm for vertical installations

- Termination: Use appropriate ferrules for stranded conductors and maintain shield continuity where applicable

Applications Across Industries

KVV control cables serve critical functions in numerous industries:

- Power Generation: Control systems in thermal, hydro, and nuclear power plants

- Manufacturing: PLC connections, sensor wiring, machine control systems

- Building Automation: HVAC controls, security systems, lighting control networks

- Transportation: Railway signaling, traffic control systems, airport infrastructure

- Mining: Control circuits in harsh underground environments

- Petrochemical: Process control instrumentation in refineries and chemical plants

Selection Criteria for KVV Control Cables

When selecting the appropriate KVV cable variant for your application, consider these factors:

- Environmental Conditions: Temperature extremes, exposure to oils or chemicals, UV exposure

- Electromagnetic Environment: Presence of VFDs, high-voltage equipment, radio transmitters

- Mechanical Stress: Risk of impact, crushing, or repeated flexing

- Installation Method: Conduit, tray, direct burial, or aerial installation

- Fire Safety Requirements: Need for flame-retardant, low-smoke, or zero-halogen properties

- Number of Cores and Cross-Section: Based on control circuit requirements and voltage drop calculations

Maintenance and Troubleshooting

To maximize service life and reliability:

- Conduct periodic insulation resistance testing

- Inspect for physical damage, especially at termination points

- Monitor for overheating signs in high-density cable bundles

- Replace cables showing signs of PVC hardening or cracking

- Ensure proper grounding of shielded variants to prevent ground loops

Frequently Asked Questions

Q: Can KVV cables be used outdoors? A: Standard KVV cables are primarily designed for indoor use. For outdoor applications, consider UV-resistant variants or install in protective conduits. Armored versions (KVV22/KVV32) offer better protection for direct burial applications.

Q: What’s the difference between KVVP and KVVP2 shielding? A: KVVP uses copper wire braid shielding providing approximately 70-80% coverage, suitable for general EMI protection. KVVP2 uses copper tape wrapping providing nearly 100% coverage, offering superior protection against high-frequency interference.

Q: How do I determine the appropriate cable size for my control circuit? A: Cable sizing depends on current requirements, acceptable voltage drop, short-circuit withstand capability, and installation conditions. For most control applications, 1.0mm² to 2.5mm² conductors are common, but calculations should be performed based on specific circuit parameters.

Q: Are there environmentally friendly alternatives to standard KVV cables? A: Yes, low-smoke zero-halogen (LSZH) variants like WDZ-KYDYD series offer reduced toxic emissions during combustion, making them suitable for confined spaces with strict fire safety requirements such as tunnels, subways, and high-occupancy buildings.

——Our Feature——

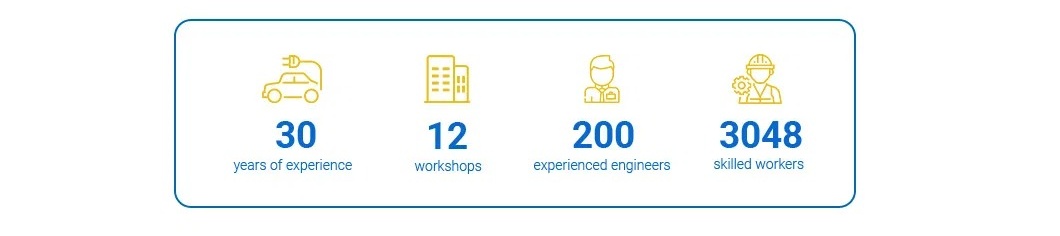

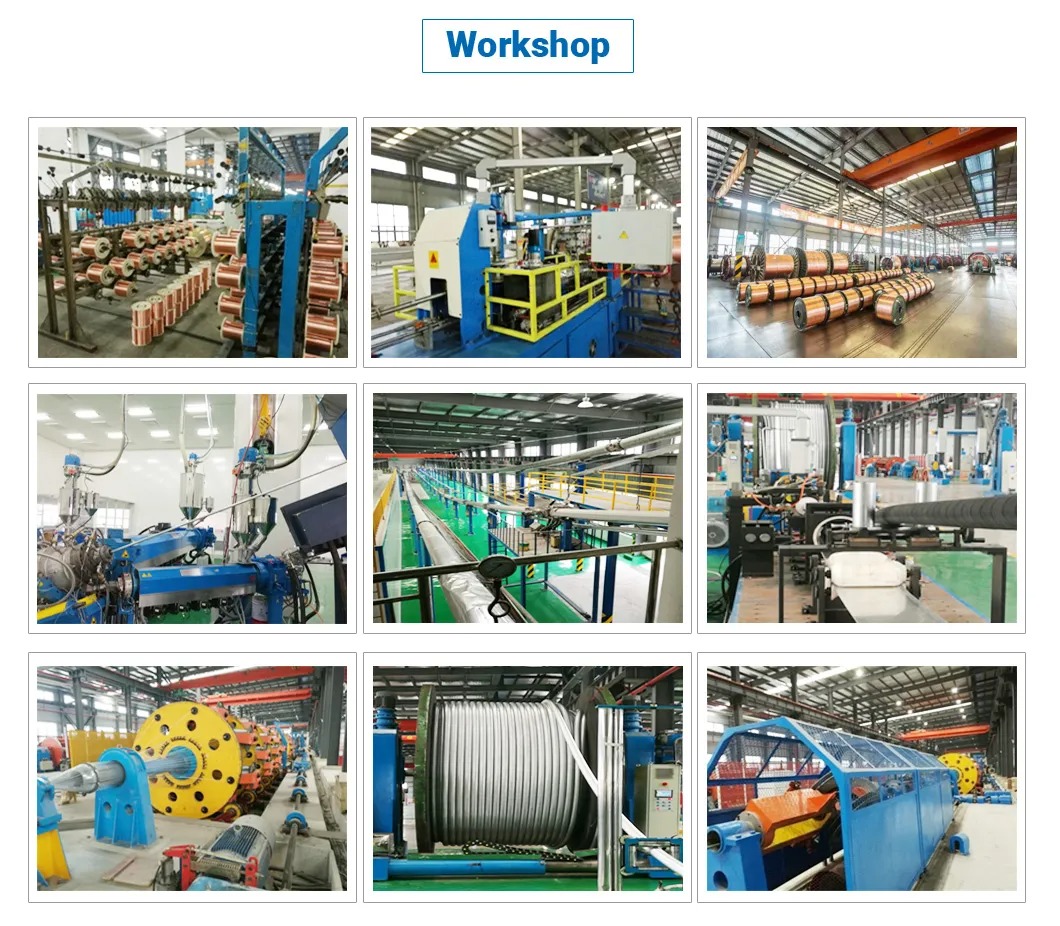

1.Imported equipment with experienced technical team

We have three plant and has 3048 employees which have 206 engineers. Plant has a series of imported production lines including Niehoff copper drawing lines, Troster Germany and Maillefer Finland 500KV VCV lines, stranding machine from Pourtier France, SKET Germany, Caballe Spain, 220KV and 35KV production line plus SIKORA X – RAY 8000 on-line eccentricity measuring unit from Germany

2.Complete certification system

We have gotten ISO 9001, ISO 14001, OHSAS 18001. Plant passed TUV, VDE, UL, CE, SAA, BS etc. certificate.

3.Perfect Production system

Our products cover LV power cable, MV power cable, HV&EHV power cable, ABC cables, ACSR/AAC/AAAC/ACAR/OPGW ,submarine cable, control cable, instrumentation cable, building wire, flexible rubber cable, fire rated cable, renewable cable, solar cable, industrial cable, Lan cable, coaxial cable etc.

4.Perfect Sales service system

We can offer the OEM/ODM service, Multiple products, Skilled Export sale engineer team, Reasonable price, Reliable quality, Friendly service.