Understanding YJV Cable

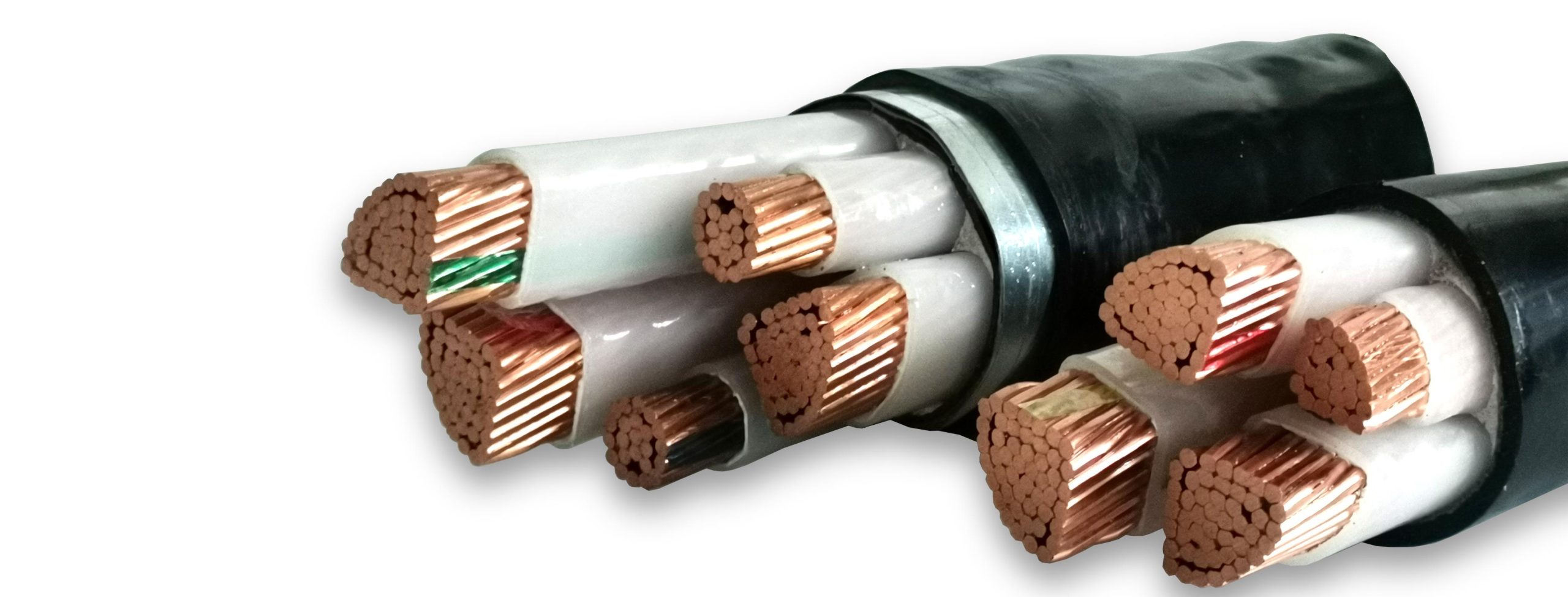

YJV cable represents one of the most widely used power distribution cables in modern electrical infrastructure. This copper conductor power cable features cross-linked polyethylene (XLPE) insulation and polyvinyl chloride (PVC) sheathing, creating a robust solution for various electrical applications.

The exceptional thermal properties of YJV cables allow them to operate continuously at temperatures up to 90°C, significantly higher than conventional PVC-insulated alternatives. This thermal advantage translates directly to higher current-carrying capacity and improved performance in demanding environments.

Electrical engineers and contractors prefer YJV cables for critical infrastructure projects where reliability, longevity, and performance under load are non-negotiable requirements. From commercial buildings to industrial complexes and utility-scale power distribution networks, YJV cables form the backbone of modern electrical installations.

Decoding the YJV Model Designation

The seemingly simple “YJV” designation contains crucial information about the cable’s construction:

- Y: Represents the insulation material – cross-linked polyethylene (XLPE). This advanced material undergoes either chemical or physical cross-linking processes that dramatically improve its thermal resistance, electrical properties, and mechanical strength compared to standard polyethylene.

- J: Indicates copper conductors. In cable designation standards used in many countries, “J” specifically denotes copper core conductors (derived from the Chinese pinyin pronunciation of “copper” or “tong”).

- V: Specifies the outer sheath or jacket material as polyvinyl chloride (PVC). This protective layer provides mechanical protection, environmental resistance, and additional electrical insulation.

Variations like ZR-YJV (flame retardant), NH-YJV (fire resistant), and WDZ-YJY (low smoke zero halogen) build upon this foundation with specialized properties for specific applications.

What is VV Cable?

VV cable is a conventional power cable featuring polyvinyl chloride (PVC) insulation and PVC sheathing. The designation breaks down as:

- First V: PVC insulation material

- Second V: PVC outer sheath material

While VV cables have served electrical systems reliably for decades, they represent older cable technology with more limited performance characteristics compared to modern alternatives like YJV. VV cables typically operate at maximum continuous temperatures of 65°C, with short-circuit temperature tolerance not exceeding 160°C.

These cables remain cost-effective solutions for general-purpose applications where extreme thermal performance or maximum current capacity isn’t required. Their widespread historical use means many existing installations still rely on VV cables, particularly in residential and light commercial settings.

Key Differences Between YJV and VV Cables

Insulation Material

The fundamental difference lies in the insulation material. YJV cables utilize cross-linked polyethylene (XLPE), which undergoes a specialized high-temperature cross-linking process that transforms the molecular structure of polyethylene. This creates a three-dimensional network that dramatically enhances thermal stability and mechanical properties.

In contrast, VV cables employ standard PVC insulation, which begins to degrade at much lower temperatures. The molecular structure of PVC remains linear and thermoplastic, softening when heated and hardening when cooled, without the permanent structural improvements achieved through cross-linking.

Thermal Performance

YJV cables’ superior thermal rating (90°C continuous operation) provides significant advantages over VV cables (65°C continuous):

- Higher current-carrying capacity for the same conductor size

- Better performance in high-ambient temperature environments

- Improved overload capability during peak demand periods

- Greater thermal stability during short-circuit events (up to 250°C vs. 160°C for VV)

Electrical Properties

The XLPE insulation in YJV cables demonstrates lower dielectric losses and reduced leakage current compared to PVC-insulated VV cables. This characteristic proves particularly valuable in systems employing residual current devices (RCDs) or ground fault protection, where lower normal leakage currents allow for more precise protection settings.

Mechanical Properties

The cross-linking process enhances mechanical strength, abrasion resistance, and cut-through resistance in YJV cables. These properties are especially important in industrial environments, outdoor installations, and applications subject to mechanical stresses during installation or service life.

Performance Comparison Table

| Characteristic | YJV Cable | VV Cable |

|---|---|---|

| Insulation Material | Cross-linked Polyethylene (XLPE) | Polyvinyl Chloride (PVC) |

| Maximum Continuous Operating Temperature | 90°C | 65°C |

| Short Circuit Temperature Rating | 250°C | 160°C |

| Conductor Material | Copper | Copper |

| Sheath Material | PVC | PVC |

| Leakage Current | Lower | Higher |

| Mechanical Strength | Higher | Standard |

| Service Life | Longer (25-30+ years) | Standard (15-25 years) |

| Chemical Resistance | Excellent | Good |

| Cost Factor | Higher initial cost | Lower initial cost |

| Current Carrying Capacity | Approximately 15-20% higher | Baseline |

Application Guidelines

When to Choose YJV Cables

- High-temperature environments: Industrial facilities, power plants, manufacturing settings

- Critical infrastructure: Hospitals, data centers, emergency systems

- Long-distance power distribution: Where voltage drop considerations are paramount

- High-load applications: Where maximum current capacity is required

- Applications requiring extended service life: Infrastructure projects with 30+ year design life

- Installations with tight space constraints: Where higher current capacity in smaller cable sizes is beneficial

When VV Cables May Suffice

- Budget-sensitive projects: Where initial cost is the primary consideration

- Indoor, controlled environments: Office buildings, residential installations with moderate loads

- Short-distance branch circuits: Where voltage drop isn’t a significant concern

- Temporary installations: Construction sites, events, short-term applications

- Retrofit projects: Where matching existing cable types is necessary for compatibility

Cost Considerations

While YJV cables typically command a 15-25% price premium over comparable VV cables, a total cost of ownership analysis often favors YJV in many applications:

- Higher current capacity allows smaller conductor sizes for the same load

- Extended service life reduces replacement frequency and lifecycle costs

- Lower failure rates minimize downtime and repair expenses

- Energy efficiency from reduced resistive losses over the installation’s lifetime

- Space savings in conduits and cable trays due to potentially smaller cable diameters

For projects with limited budgets but requiring some YJV benefits, hybrid approaches can be effective—using YJV for critical or high-load circuits while employing VV for general lighting or low-power branch circuits.

Frequently Asked Questions

Q: Can YJV and VV cables be connected together in the same circuit?

A: Yes, YJV and VV cables can be connected in the same circuit, but the circuit’s current rating must be limited to the lower-capacity VV cable specifications. This practice is generally not recommended for new installations but may be necessary during retrofits or repairs.

Q: Is YJV cable suitable for direct burial?

A: Standard YJV cable isn’t rated for direct burial. For underground applications, use armored variants like YJV22 or YJV32 cables, which feature steel tape or steel wire armor for mechanical protection against soil pressure and potential damage during installation.

Q: How do temperature ratings affect cable selection?

A: Temperature ratings directly impact current-carrying capacity. A YJV cable rated for 90°C can carry approximately 15-20% more current than a comparable VV cable rated for 65°C. This allows for smaller conductor sizes or longer circuit runs with equivalent voltage drop.

Q: What’s the expected service life difference between YJV and VV cables?

A: YJV cables typically offer 25-30+ years of service life under proper operating conditions, compared to 15-25 years for VV cables. The superior thermal stability of XLPE insulation significantly reduces aging effects, particularly in applications with frequent thermal cycling or continuous high loads.

Conclusion

The choice between YJV and VV cables represents a balance between performance requirements and economic considerations. While YJV cables command a higher initial investment, their superior thermal performance, extended service life, and enhanced electrical properties often justify the additional cost in demanding applications.

For modern electrical installations where reliability, longevity, and performance under load are priorities, YJV cables increasingly represent the industry standard. However, VV cables remain viable solutions for budget-conscious projects with less demanding operational requirements.

Electrical professionals should evaluate each project’s specific requirements—including ambient temperature, load profiles, installation environment, expected service life, and total lifecycle costs—before selecting the appropriate cable type. When in doubt, consulting with cable manufacturers or experienced electrical engineers can help optimize this critical selection for your specific application.