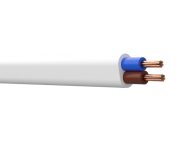

Product Structure

The wire and cable are composed of a conductor, an insulation layer, a shielding layer and a protective layer.

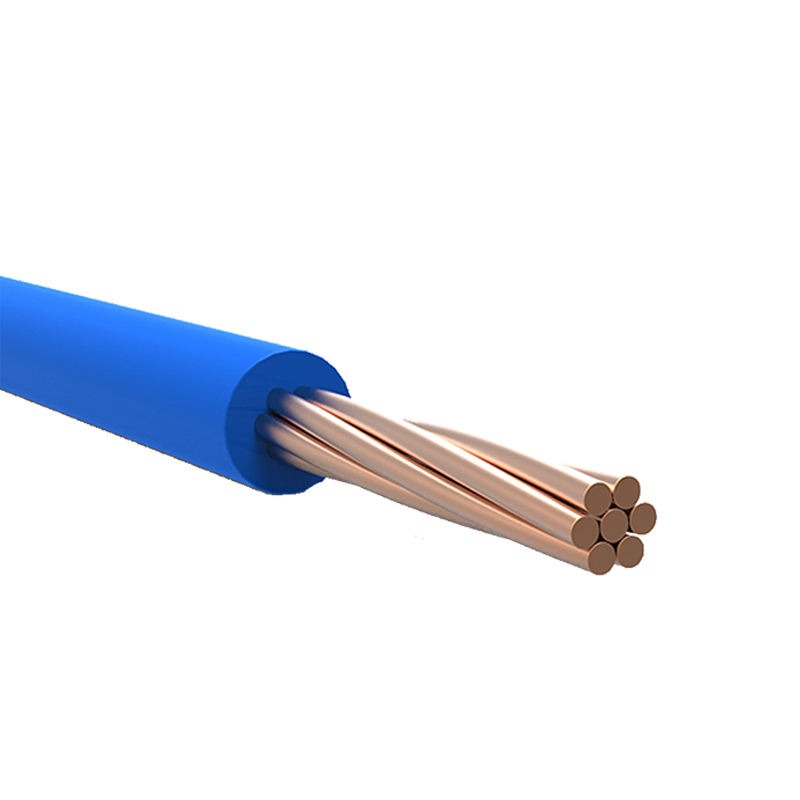

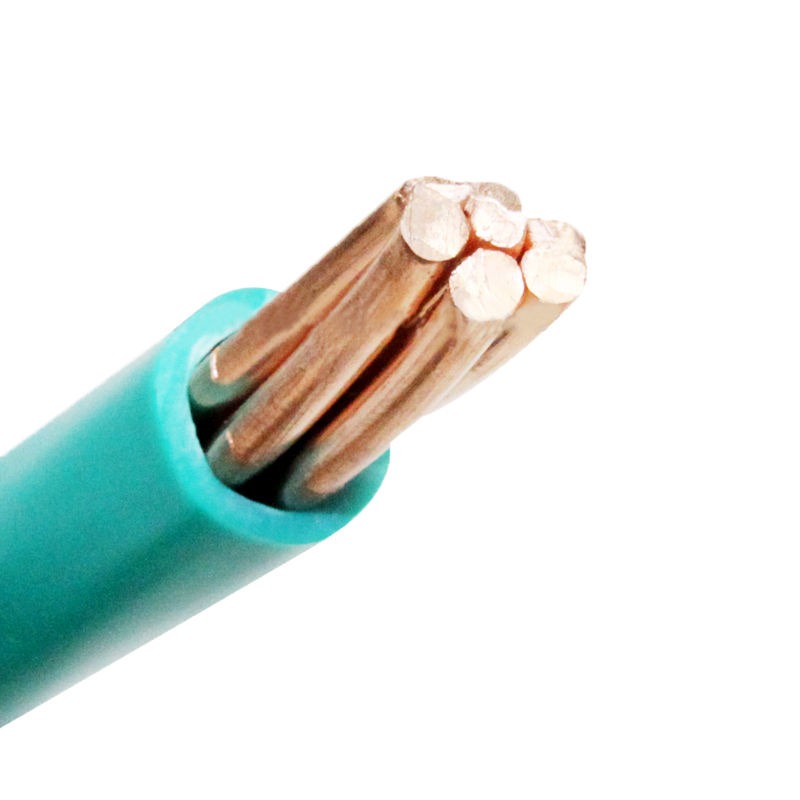

1.Conductor :

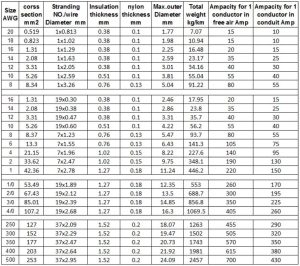

<a>. Copper or Aluminum. Stranded uncoated copper conductors per ASTM-B3, ASTM-B787, and ASTM-B8

<b>. Conductor Type: Stranded conductor or solid conductor

<c>. The conductor is the conductive part of the wire and cable, which is used to transport electrical energy and is the main part of the wire and cable.

2. Insulation:

<a>. PVC . Color-coded Polyvinyl Chloride (PVC) heat and moisture resistant, flame-retardant compound per UL 1063 and UL 83

<b>. Insulation layer is to electrically isolate the conductor from the ground and conductors of different phases from each other to ensure the transmission of electrical energy. It is an indispensable part of the wire and cable structure.

3. Shield :

Wires and cables of 15KV and above generally have conductor shields and insulation shields.

4. Outer Sheath / Jacket:

Nylon, THHN tough, polyamide, Nylon outer covering per UL 1063 and UL 83 Slick Nylon outer jacket for easy pulling.

5. Color Code: Red, orange, yellow, yellow-green, blue, purple, gray, white or as your requirement

6. The protective layer

The function of the protective layer is to protect the wires and cables from the invasion of foreign impurities and moisture, and to prevent external power from directly damaging the power cables.

7. Working Temperature: At the rated drying temperature is 90 degrees Celsius, at a nominal temperature of 75 ° C wet, rated THWN.

Most THHN building wire in the wet and dry temperature ratings are marked with THHN / THWN double rating.

When used as Type THHN conductor suitable for oil or cooling liquid temperature did not exceed wet or dry place at 90 ° C or 75 °C to. When used as an MTW type, for conductors of 90 ° C in a dry place, moist places or places exposed to oil or coolant is not above 60 ° C is used.

8. Building Applications THHN Wire: THHN Wire representative of a high heat thermoplastic nylon coating.

Machine for the control circuit wiring or some device. It is suitable for the new configuration of rewiring or 600 volts applied,and suitable for general use in the National Electrical Code (NEC) defined.

THHN Wire Features

1. Nylon thread has superior safety performance such as anti-termite, anti-rat bite, and good heat resistance (heat resistance up to 200 degrees Celsius).

2. Nylon wire has no harm to the surrounding environment. It is green and environmentally friendly. It is a better wire for home decoration equipment power supply and lighting.

3. It is light in weight and smooth in appearance. Because nylon itself has lubricity, it is not easy to scratch when threading, and it is easy to lay through the pipe. It brings convenience and economy to installation and laying. The use of nylon as a sheath has a bright appearance, small heat deformation and excellent Thermal stability.

4. It has high mechanical strength and excellent wear resistance, cold resistance, surface hardness, bending strength, strong impact, chemical resistance, oil resistance, gasoline resistance and self-lubrication.